Conveyor rollers play a quiet but vital role in PCB manufacturing. They guide delicate boards through complex processes. In wet lines, these cylinders ensure steady movement. Production managers and engineers know their worth. A snag here slows everything. This post breaks down how conveyor rollers work in PCB production. It covers basics to real-world use. Readers handling lines or sourcing parts will gain insights. Strong rollers mean reliable runs. They cut waste and keep output high.

Core Functions of Conveyor Rollers

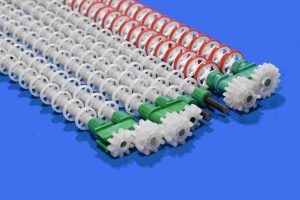

Conveyor rollers act as the wheels of production lines. They support and move loads. In PCB setups, boards slide over them. Each roller turns under weight. This creates smooth flow. No jerks or stops. Bearings inside make spins easy. Frames hold them in place. Spacing sits around six inches. This fits standard board sizes.

In wet processing, rollers face sprays and chemicals. They need to resist corrosion. Steel with coatings works well. Seals protect bearings from moisture. Without them, rust sets in fast. Lines halt for fixes. Rollers link to gears for drive. Bushings reduce wear. All parts work together. Boards pass from cleaning to etching without hitch.

Rollers handle light loads like PCBs. Diameters run small. One to three inches covers most. Length matches line width. Custom fits adapt to needs. In horizontal lines, they lay flat. Gravity or power pushes boards along. This setup suits volume runs. Thousands of boards daily.

Drive Mechanisms Behind Rollers

Power comes from motors or chains. Electric drives spin shafts. Gears pass force to rollers. They turn at same speed. Loads move even. In gravity types, tilt does the job. Downhill pull shifts boards. Chains link for heavy pulls or turns.

Sensors watch the flow. They spot blocks. Lines pause to clear. This guards thin boards from damage. In PCB wet stages, drive must stay gentle. No high speeds. Steady pace lets chemicals work right.

Conveyor Rollers in PCB Wet Processing

PCB production relies on wet steps. Cleaning, developing, etching. Rollers guide boards through. They ensure even exposure. Brushes scrub oxides first. Rollers position boards under them. Nylon filaments clean gentle. No scratches on copper.

After rinse, sponge rollers absorb water. They pair with main rollers. This dries surfaces quick. Wet spots cause issues later. Air blasts follow. Rollers set the timing. Boards move at right speed. Too fast skips clean. Too slow backs up.

Etching tanks use rollers too. Seals contain acids. Rollers resist eat-away. They keep boards level. Even etch means sharp traces. Post-etch rinse cascades water. Rollers channel flow. No pools form.

In drying, air knives blow hard. Rollers hold boards steady. High air strips moisture. Lines run continuous. From start to end, rollers tie it all.

Integration with Other Components

Rollers don’t stand alone. Gears drive them. U-blocks align edges. They prevent shifts. Transmission parts link sections. Bushings quiet motion. Peripheral items add function. Filters clean sprays. Nozzles direct flow.

Consumables refresh often. Seals wear from chemicals. Swap them regular. All support rollers. Strong setup means high yield. Fewer bad boards.

Types of Rollers for PCB Lines

Several roller types fit PCB needs. Powered ones use motors. They cover long straight paths. Ideal for full lines. Gravity rollers tilt down. Short drops between stages. Low cost, no power.

Chain-linked rollers handle turns. They pull heavy if needed. But PCBs stay light. Cross-transfer mixes rollers and chains. Shifts direction ninety degrees. Useful for sorting.

Turntables spin loads. Tight spaces benefit. Incline types climb small rises. Lifts pair for big jumps.

Wet lines favor sealed bearings. They block sprays. Materials like stainless fight corrosion. Nylon or rubber coats add grip. Slippery boards stay put.

Choosing Rollers for Specific Tasks

Load dictates type. PCB light, so slim rollers work. Speed sets diameter. Fast lines need low drag. Slow ones grip better.

Environment picks material. Wet calls for resistant coats. Dry allows basic steel. Custom lengths match board widths. Three-inch diameter suits pallets if used.

Table shows matches:

| Roller Type | Drive | PCB Stage | Capacity |

| Powered | Motor | Full line | Light to medium |

| Gravity | Tilt | Rinse drop | Light |

| Chain | Pull | Turn points | Medium |

| Cross | Mix | Shift path | Light |

This helps pair types to jobs. Right pick smooths flow.

How Rollers Operate in Daily Production

Day starts with setup. Frames level. Rollers spin free. Bearings lube. Loads enter. Weight turns rollers. Boards glide.

In wet, sprays hit. Rollers shed water. Grooves drain. Sponges press dry. Air finishes.

Sensors scan. Gaps fine. Blocks trigger stop. Clear and go.

The equipment is usually in production 24 hours a day. During long holidays or at the end of the year, it is maintained and cleaned, and any broken parts are replaced in a timely manner.

Advantages in PCB Manufacturing

Rollers speed lines. Boards move quick. Output rises. Labor drops. No hand carry.

Quality holds. Even flow means uniform etch. Fewer defects. Waste cuts.

Safety up. Less lift hurts. Auto moves guard hands.

Costs ease. Low power use. Parts last long. Downtime low.

Flex for changes. Modules add easy. Lines grow with demand.

Teams focus high tasks. Checks and fixes. Brand builds strong. Reliable supply wins trust.

Common Issues and Solutions

Wear tops list. Chemicals grind. Coats protect. Swap schedules help.

Jams from misalign. Level frames. Clear paths.

Noise from loose. Tighten bolts. Lube cuts rub.

Heat in dry zones. Vent well. Cool materials cope.

Solutions straightforward. Train teams. Stock parts. Issues fade.

Emerging Developments in Roller Technology

Materials lighten. Composites resist better. Last longer.

Mods snap fit. Swaps fast. Lines adapt quick.

Green options rise. Recycled builds. Low friction saves energy.

Trends push efficiency. Rollers follow suit.

Shenzhen Qixingyuan Machinery Equipment Co., Ltd.: Supplier of PCB Horizontal Line Wet Processing Spares

Shenzhen Qixingyuan Machinery Equipment Co., Ltd. serves as a supplier for PCB horizontal line wet processing equipment spares and parts. Founded in 2008, it integrates design, production, and sales. Multiple national patents highlight its technical edge. The firm concentrates on components that enhance wet segment performance.

Its lineup features air knives for drying, brush and sponge rollers for cleaning, seal strips for etching tanks, and transmission elements such as U-blocks and gears. Materials endure corrosive environments, fitting acidic or alkaline conditions. Customization tailors to line speeds and board dimensions.

The 3000 square meter facility employs over 50 staff. Annual production reaches millions of units. Exports span Europe, Asia, and the Americas. One-stop services cover from initial schemes to installation. Flexible minimum orders suit small buyers, with delivery averaging seven days. Agents appreciate marketing support and competitive pricing. This builds lasting partnerships with manufacturers. It helps maintain continuous operations, boosting throughput while trimming expenses. The commitment to innovation and quality strengthens its position in global electronics supply chains.

Conclusion

Conveyor rollers anchor PCB production lines. They enable seamless movement through critical wet processes. Understanding their mechanics empowers better system design and maintenance. Reliable rollers translate to consistent quality and efficiency. For those in the field, investing in durable components pays dividends in performance and reputation.