Industry Background

Developing and etching are critical stages in PCB manufacturing, directly determining circuit accuracy and yield. These processes require precise chemical control, uniform spraying, and high equipment reliability.

Common Developing and Etching Problems

Problem 1: Uneven etching

Non-uniform spray distribution causes over-etching or under-etching.

Problem 2: Nozzle clogging

Chemical crystallization and impurities block nozzles, reducing process stability.

Problem 3: Severe corrosion

Strong acidic and alkaline environments accelerate component degradation.

Engineering Causes

-

Insufficient corrosion resistance of spray materials

-

Unstable chemical flow and pressure control

-

Long-term chemical fatigue of components

Qixingyuan Developing and Etching Solution

Qixingyuan provides corrosion-resistant and stable wet processing components for PCB developing and etching lines, ensuring uniform spraying and consistent chemical reactions.

Core components include:

-

PP / PVC / PVDF acid-resistant nozzles

-

Chemical filtration systems

-

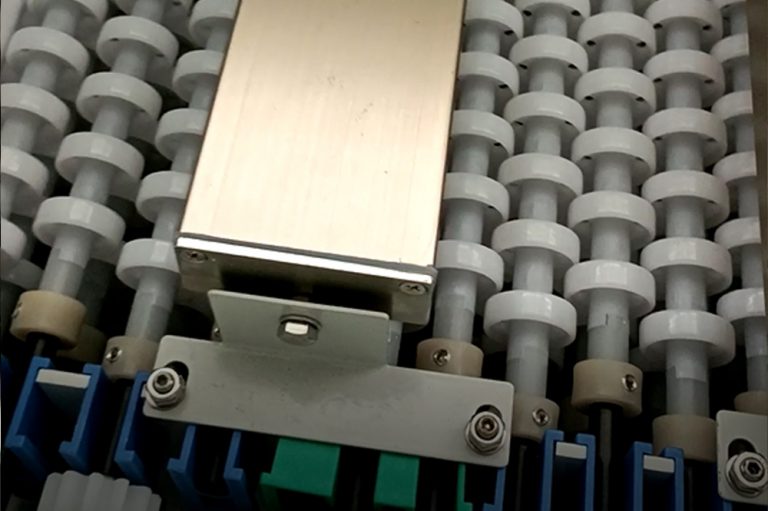

Transmission and support components

Application Results

-

Improved etching consistency

-

Reduced circuit defects and rework

-

Lower nozzle blockage and maintenance frequency

-

Extended equipment service life

Typical Equipment Use

Spray-Type Developer / Etcher

Chemical Circulation & Filtration System

Automatic Chemical Concentration Controller