In the fast-paced world of PCB (Printed Circuit Board) manufacturing, efficiency and precision are paramount. As the backbone of many electronic devices, PCBs require thorough cleaning and treatment during the manufacturing process to ensure high quality and functionality. One of the critical components used in this process is the brush roller. These rollers are vital for various stages of PCB manufacturing, ensuring the removal of contaminants, smoothing surfaces, and preparing PCBs for further processing. In this blog, we will explore the roles of different types of brush rollers—Ceramic, Nylon, Non-woven, Spring, Grinding, and Mechanical High-Density—and how each plays a part in optimizing the PCB production process.

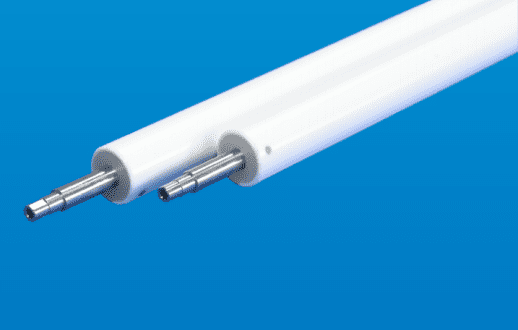

1. Ceramic Rollers for PCB scrubbing and cleaning

Ceramic rollers are often used in PCB manufacturing due to their high durability and resistance to wear and tear. These rollers are known for their ability to handle high temperatures and maintain their effectiveness over long periods. In PCB manufacturing, ceramic rollers are particularly useful for cleaning and polishing during the etching process. They efficiently remove contaminants like dust and oxidation from the board surface without causing any damage.

The core advantage of ceramic brush rollers lies in their high-density construction, which allows for effective scrubbing and cleaning. Their hardness also ensures that they can withstand aggressive chemical processes often used in PCB manufacturing, making them a reliable choice for manufacturers who need long-lasting solutions.

Shenzhen Qixingyuan Machinery Equipment Co., Ltd. offers a wide range of ceramic rollers, expertly crafted to deliver high performance in demanding PCB processes. Their rollers are known for their excellent durability, ensuring long-term reliability and minimal maintenance costs.

2. Nylon Brush Rollers for PCB Cleaning

Nylon brush rollers are another popular choice in PCB manufacturing, known for their flexibility and versatility. These rollers are widely used in pre-treatment and cleaning processes where gentle yet effective scrubbing is required. The elasticity and durability of nylon bristles ensure that the surface of the PCB is thoroughly cleaned without damaging sensitive components.

Nylon rollers are especially suitable for situations where PCB surfaces are delicate or when cleaning requires a lighter touch. They can efficiently remove oils, dust, and minor oxidation while preventing scratches on the PCB’s surface.

Qixingyuan offers nylon brush rollers designed for high-efficiency cleaning. These rollers are available in various sizes and densities, making them adaptable to different line speeds and PCB contamination levels. The durable, corrosion-resistant design ensures that they can withstand the rigors of PCB manufacturing, making them an excellent investment for businesses seeking consistent cleaning performance.

3. Non-Woven Brush Rollers for PCB Surface Preparation

Non-woven brush rollers are designed for PCB manufacturing processes that require enhanced surface cleaning and finishing. These rollers are typically used for tasks like surface preparation before electroplating or soldering. The non-woven fabric ensures that contaminants are removed without leaving residue or fibers behind, which is essential for achieving the high-quality finish required for PCB functionality.

Non-woven brush rollers are highly effective in removing oxidation and other residues that could compromise the integrity of the PCB. They also provide superior cleaning power without the need for aggressive scrubbing, making them ideal for delicate PCBs or sensitive applications.

Qixingyuan’s non-woven brush rollers are engineered for precision cleaning. They come with customizable brush sizes and densities to meet specific production requirements, helping manufacturers achieve top-notch cleaning results while maintaining board integrity.

4. Spring Brush Rollers for Adaptive PCB Cleaning

Spring brush rollers, unlike traditional brush rollers, feature spring-loaded bristles that provide an adaptive scrubbing action. These rollers are highly effective in PCB applications where varying surface conditions demand dynamic cleaning pressure. The spring mechanism allows the brush roller to adjust to different surface heights, ensuring consistent and thorough cleaning across the entire PCB surface.

Spring brush rollers are particularly useful in PCB lines where uneven surfaces are common, as they can effectively compensate for height variations, ensuring uniform cleaning without damaging the PCB.

At Qixingyuan, spring brush rollers are designed to provide the perfect balance of cleaning efficiency and board protection. With a range of custom options, these rollers are a reliable solution for dynamic PCB cleaning processes.

5. Grinding Brush Rollers for PCB Polishing and Deburring

Grinding brush rollers play a critical role in PCB manufacturing when a more aggressive cleaning approach is needed. These rollers are used in the grinding and polishing stages of PCB manufacturing, where they help remove stubborn oxidation, burrs, or residues from the board’s surface.

Grinding brush rollers typically feature more abrasive materials compared to standard cleaning rollers. They are ideal for preparing PCB surfaces for further processing, such as soldering or coating, by ensuring that the board surface is smooth and free from impurities.

Qixingyuan’s grinding brush rollers offer superior wear resistance, making them an excellent choice for high-intensity cleaning processes. These rollers are customizable to meet the specific demands of different manufacturing lines, ensuring optimal performance and consistent results.

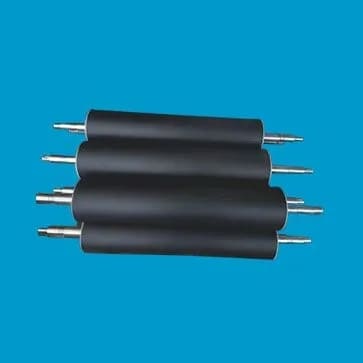

6. Mechanical High-Density Brush Rollers for PCB Cleaning

Mechanical high-density brush rollers are designed to provide a powerful scrubbing action for thorough cleaning in PCB manufacturing. These rollers feature high-density bristles, which allow them to handle even the most challenging contaminants, such as heavy oxidation and soldering residues. They are commonly used in PCB cleaning systems where efficiency and durability are essential.

The main benefit of mechanical high-density brush rollers is their ability to maintain high cleaning effectiveness over long periods, even in harsh chemical environments. These rollers are often used in industrial-scale PCB production lines due to their reliability and robust design.

Qixingyuan provides mechanical high-density brush rollers tailored for high-efficiency cleaning. These rollers are designed to meet the specific needs of PCB manufacturers, offering customization options to fit various production processes.

Conclusion

In PCB manufacturing, brush rollers are indispensable for ensuring that each board is cleaned thoroughly and efficiently, setting the stage for high-quality production. From ceramic to nylon, non-woven to spring, grinding to mechanical high-density brush rollers, each type has its unique strengths and applications. Selecting the right brush roller is crucial to optimizing the production process, reducing defects, and enhancing product yield.

Meet Shenzhen Qixingyuan Machinery Equipment Co., Ltd.

Shenzhen Qixingyuan Machinery Equipment Co., Ltd. is committed to providing high-quality PCB equipment accessories, including a wide range of brush rollers designed to meet the specific needs of various manufacturing stages. With a focus on durability, efficiency, and customer satisfaction, Qixingyuan ensures that every product is crafted to the highest standards, supporting PCB manufacturers in achieving smooth and reliable production lines.