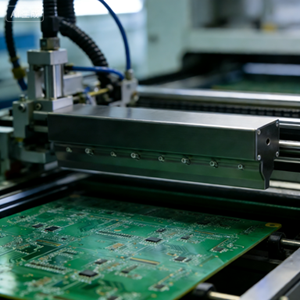

Air knives play a key role in modern circuit board production. These tools deliver focused streams of air to handle tasks like drying and cleaning. In PCB lines, they help remove moisture after wet processes, keeping boards free from defects. Factories rely on them to maintain quality during etching or plating stages. Air knives in PCB manufacturing ensure smooth operations by blowing away liquids without contact, reducing risks of damage. This post dives into various types, looking at materials and shapes that suit different needs. Providers such as Shenzhen Qixingyuan Machinery Equipment Co., Ltd. ( Qixingyuan) deliver options built for these demands, blending durability with performance.

Understanding Air Knives and Their Role in PCBs

Air knives create a curtain of high-speed air. They replace older methods like wiping or heating, which can harm delicate boards. In PCB setups, air knives fit into horizontal lines for wet processing. They cut down on water spots that lead to shorts or corrosion. Data from industry reports show that proper air knife use can boost yield rates by up to 15% in high-volume runs. Qixingyuan focuses on parts that integrate seamlessly into these lines, offering reliable airflow for consistent results.

How Air Knives Function in Production Lines

The basic setup involves a blower pushing air through a narrow slot. This forms a uniform sheet that strips away residues. In PCB contexts, they often follow rinsing tanks. For instance, after chemical baths, boards move under the air stream, emerging dry in seconds. Such efficiency matters in facilities producing thousands of units daily.

Core parts include the plenum chamber and inlet ports. Designs vary to match line speeds. Some feature adjustable slots for finer control. Qixingyuan crafts these with precision, ensuring even distribution across board widths up to 600mm.

Air knives adapt to specific tasks. In drying, they prevent oxidation on copper layers. Cleaning versions remove particles that could cause failures in assembly. Their non-contact approach suits sensitive components, avoiding scratches or static buildup.

Materials Used in Air Knives for PCB Applications

Material choice affects longevity and compatibility. Stainless steel air knives resist harsh chemicals common in PCB wet lines. They handle acids without degrading, lasting years in tough environments. Aluminum options weigh less, easing installation in compact setups. Titanium variants excel in corrosive settings, like those with strong etchants. PVC types offer cost-effective solutions for milder uses.

Each material brings trade-offs. Stainless steel adds strength but costs more. Aluminum cuts weight by 30%, ideal for overhead mounts. In practice, a factory might pick titanium for lines dealing with aggressive solutions, extending service intervals.

Comparing Material Strengths

Here’s a quick look at how materials stack up:

| Material | Durability | Corrosion Resistance | Weight | Common PCB Use |

|---|---|---|---|---|

| Stainless Steel | High | Excellent | Medium | Chemical rinsing |

| Aluminum | Medium | Good | Low | General drying |

| Titanium | Very High | Superior | Medium | Harsh etchants |

| PVC | Low | Fair | Low | Light cleaning |

Qixingyuan supplies these materials, tailoring them to PCB needs. Their stainless steel versions, for example, feature smooth surfaces that minimize turbulence.

Beyond basics, consider exposure levels. In a line with frequent acid dips, stainless or titanium prevents breakdowns. Weight matters for portable units. Qixingyuan’s range covers these, with options that fit existing equipment without major changes.

Shapes influence airflow patterns. Straight designs provide wide coverage for flat boards. Curved or circular ones target edges or holes.

Shapes and Configurations of Air Knives

Different types of air knives come in various forms to tackle specific challenges. Straight blades span the board width, delivering even blasts. Circular knives encircle parts for all-around drying, useful in post-plating steps. Cone-shaped manifolds focus air into tight spots, like vias on dense boards.

In a typical setup, straight knives mount above conveyors. They clear water from surfaces as boards pass. Circular types wrap around cylindrical components, though less common in flat PCB work. Cone designs help in spot cleaning, directing air precisely.

Straight vs. Curved Designs

Straight shapes dominate PCB lines for their simplicity. They create broad curtains that cover entire panels. Curved options bend the flow, following board contours in specialized machines. A shift from straight to curved can improve drying on irregular shapes by 20%, based on line tests.

Qixingyuan offers both, with ccustomizable in interface type (G1/4, G1/2), length, and air gap width. Their straight models integrate into horizontal wet lines, enhancing throughput.

Specialized Shapes for Advanced Needs

Beyond standards, some knives feature manifolds with multiple outlets. Spyder types branch out, hitting hard-to-reach areas. In PCB manufacturing, these clean intricate traces without excess pressure. Tornado configurations swirl air for better particle removal.

Such variety allows factories to match tools to processes. For high-density boards, a spyder setup ensures no moisture lingers in crevices, cutting reject rates.

Benefits of Air Knives in PCB Processes

Air knives streamline workflows. They speed up drying, letting lines run faster. In etching, they blow off etchants quickly, preserving fine lines. Plating benefits from clean surfaces, improving adhesion.

Real-world gains include lower energy use compared to ovens. A study from electronics firms noted 25% savings in power. Qixingyuan’s products emphasize efficiency, with designs that reduce air consumption while maintaining force.

Integration in Wet Processing Lines

Wet processes involve multiple rinses. Air knives slot in after each, preventing carryover. This keeps chemicals separate, avoiding contamination. In horizontal lines, they align with rollers for seamless flow.

Qixingyuan provides spares that fit these integrations. Their air knives pair with absorption rollers, creating full drying systems.

Challenges and Solutions with Air Knives

Noise can be an issue in enclosed spaces. Modern designs incorporate silencers. Maintenance involves checking slots for clogs, especially in dusty environments.

Solutions include regular inspections. Qixingyuan builds in easy-access features, simplifying upkeep.

Addressing Common Issues

Airflow inconsistencies arise from poor blower matches. Pairing with right pressures fixes this. In PCB settings, static can attract dust; grounded materials counter it.

Qixingyuan’s titanium knives include anti-static elements, suiting sensitive boards.

Keep inlets clean. Adjust gaps based on board thickness. Training staff on these steps extends life.

About Shenzhen Qixingyuan Machinery Equipment Co., Ltd.

Shenzhen Qixingyuan Machinery Equipment Co., Ltd. stands out as a supplier of PCB horizontal line wet processing equipment spares and parts. Founded in 2008, this high-tech firm combines design, production, and sales to serve the electronics sector. Their lineup covers air knives, rollers, gears, and more, all aimed at boosting line efficiency. With national patents under their belt, they prioritize innovation in wet processing tools.

The company excels in materials like stainless steel and titanium for air knives, crafted to withstand PCB chemicals. Their products fit into drying and cleaning stages, helping factories cut defects and speed output. Qixingyuan’s approach centers on quality, with rigorous testing ensuring parts last in demanding runs. Customers benefit from tailored solutions, like custom shapes for specific lines.

Beyond parts, they offer measurement tools and consumables, rounding out PCB needs. Their commitment shows in global reach, empowering manufacturers with reliable gear. Integrity drives their work, fostering long-term ties. As PCB tech advances, Qixingyuan adapts, delivering spares that keep lines humming. This focus makes them a go-to for spares in wet processes, supporting everything from small shops to large plants.

Conclusion

Air knives remain essential in PCB manufacturing, offering versatile solutions through varied materials and shapes. From stainless steel for tough environments to aluminum for lighter duties, choices abound. Benefits of air knives in PCB production include faster drying and cleaner boards, directly impacting quality. As lines evolve, these tools adapt, ensuring efficiency. For those in the field, selecting the right type pays off in smoother operations and fewer issues.

FAQs

What makes stainless steel air knives ideal for PCB wet processing?

Stainless steel air knives hold up well against chemicals in PCB lines. They resist corrosion from acids and rinses, lasting longer than other materials. In practice, they deliver steady air curtains that dry boards evenly after etching or plating. This cuts down on water spots that cause electrical faults.

How do air knife shapes affect performance in circuit board drying?

Shape dictates air delivery. Straight knives cover wide areas, suiting flat PCBs on conveyors. Curved or cone types target edges and holes, removing moisture from tricky spots. In dense boards, this precision prevents residues that lead to shorts.

Why choose titanium air knives for harsh PCB environments?

Titanium air knives excel in corrosive settings, like those with strong etchants. They withstand degradation better than steel, extending life in wet lines. This material keeps airflow consistent, crucial for even solder leveling in HASL processes.