Industry Background

In LCD manufacturing, cleaning processes are essential across cutting, grinding, developing, etching, and inspection stages. As LCD panels become larger, thinner, and more precise, cleaning systems must efficiently remove particles, chemical residues, and moisture without damaging delicate surfaces, ensuring stable downstream processing and high yield.

Common Cleaning Problems in LCD Line

Problem 1: Surface particle residue

Incomplete cleaning leaves dust or debris on glass surfaces, affecting display uniformity and bonding quality.

Problem 2: Water marks and chemical residue

Residual moisture or chemicals after cleaning lead to surface defects.

Problem 3: Uneven cleaning due to brush wear

Aging or mismatched brush rollers cause uneven pressure and increase scratch risk.

Problem 4: Frequent maintenance

High humidity and chemical exposure shorten component lifespan and increase downtime.

Engineering Causes

-

Uneven water flow and mechanical contact at high line speeds

-

Insufficient chemical resistance of cleaning materials

-

Inefficient water absorption and drainage

-

Long-term fatigue in wet processing environments

Qixingyuan LCD Cleaning Solution

Shenzhen Qixingyuan Machinery Equipment Co., Ltd. (Qixingyuan) provides reliable components for LCD wet cleaning lines. Through corrosion-resistant materials and precision manufacturing, Qixingyuan ensures stable and efficient cleaning performance.

Core components include:

-

Nylon brush rollers

-

PVA / PU sponge rollers

-

Cleaning spray nozzles and filtration components

-

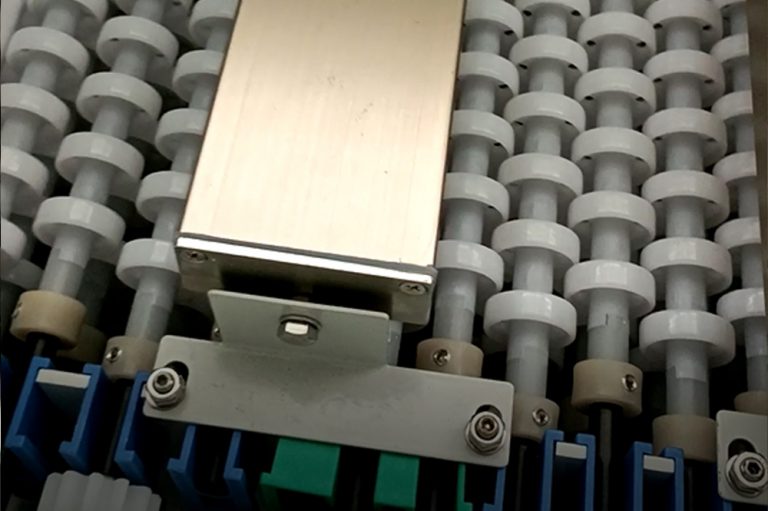

Transmission and support parts

Application Results

-

Reduced surface particle contamination

-

Lower risk of water marks and chemical residue

-

Improved cleaning uniformity with fewer scratches

-

Extended maintenance intervals

-

Higher overall LCD panel yield

Used in the Following Equipment

-

Post-cutting LCD glass cleaning

-

Post-grinding and polishing cleaning stages

-

Pre- and post-developing / etching cleaning

-

Cleaning before AOI inspection