1.Industry Background

In PCB automated production lines, transmission systems are critical for stable board movement through AOI, exposure, etching, cleaning, and printing stages. As PCB designs move toward ultra-thin and high-precision circuits, transmission components must maintain high wear resistance, precise alignment, and long-term stability.

2.Common Transmission Problems in PCB Lines

Problem 1: Board deviation and vibration

Severe wear of transmission rollers leads to uneven support force, causing panel misalignment and vibration during AOI inspection and exposure processes.

Problem 2: Sliding and board stacking

Aging rubber rollers and uneven belt tension reduce friction stability, resulting in frequent slipping, stoppage, and panel accumulation.

Problem 3: Excessive noise and line instability

Insufficient transmission gear precision increases backlash and vibration, affecting overall line stability.

Problem 4: High maintenance frequency

Short bearing and bushing lifespan under continuous operation raises daily maintenance costs and downtime risk.

3.Engineering Causes Behind Transmission Failures

Long-term exposure to moisture and chemical residues accelerates material wear

Inconsistent friction coefficients in aging rollers cause unstable torque transfer

Gear backlash and bearing clearance increase vibration at high speeds

4.Qixingyuan Transmission System Solution

Shenzhen Qixingyuan Machinery Equipment Co., Ltd. (Qixingyuan) provides precision-machined transmission components designed for PCB wet processing environments. By combining wear-resistant materials, accurate dimensional control, and long-life structural designs, these solutions ensure stable, continuous board transmission across multiple process stages.

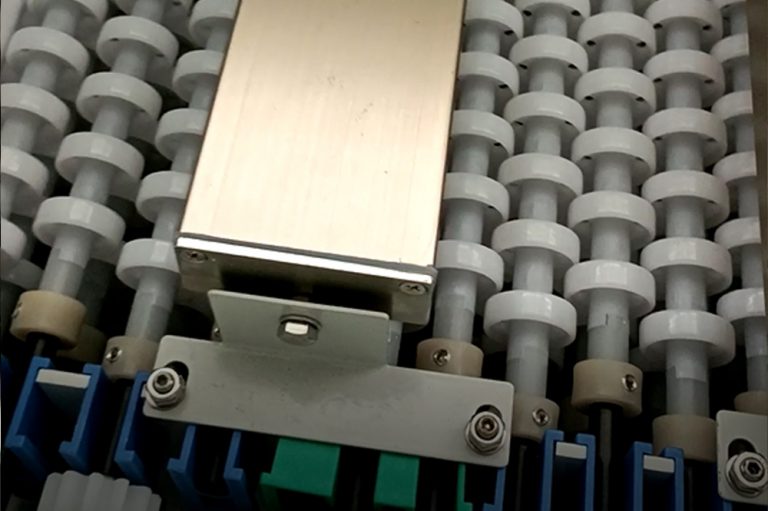

Core components include:

Transmission and expansion rollers

Rubber-coated rollers (soft and hard)

Synchronous pulleys and sprockets

Bearings, sleeves, bushings, and pulley assemblies

5.Application Results

After implementation, PCB manufacturers typically achieve:

Significant reduction in board shift rate

Reduced surface scratches and vibration

Lower operating noise and smoother line movement

Extended equipment maintenance cycles

5–15% improvement in overall line capacity (depending on equipment condition)

6.Typical Equipment Used

Automatic Loader/Unloader / Robotic Arm Interface Conveying Unit

Transfer Machine / Shuttle Cart / High-Precision Positioning Conveyance Module

Conveyor (Platen/Roller Type) / Specialized Conveying System for Abrasive Brush Machines

Fully Automated Overhead Crane (OHT) / Material Handling Vehicle (MHV) / Continuous Conveyance Line