Air knife systems play a key role in many industries. They blow high-speed air to dry surfaces, remove dust, or create barriers. If you’re in manufacturing, you might wonder how to pick the right one. This guide walks you through the basics. It helps you match a system to your specific setup. Shenzhen Qixingyuan Machinery Equipment Co., Ltd. ( Qixingyuan), known for reliable air knives, offers options that fit various needs. Their products handle tough environments well.

Understanding Air Knife Systems

Air knives create a thin sheet of air. This air moves fast to clean or dry items on a line. Think of it as a powerful fan focused into a narrow stream.

What is an Air Knife?

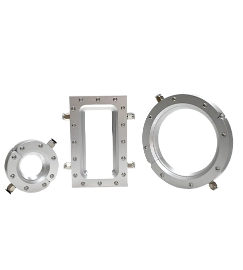

An air knife is a tool that uses compressed air or a blower to make a curtain of air. It comes in straight or curved shapes. The air exits through a slot, hitting surfaces evenly. Qixingyuan makes these in different forms. Some are straight for flat lines. Others are ring-shaped for round objects. You connect them to a blower or compressor. The setup pushes air out at high speed. This removes water or particles without touching the product.

Air knives replace old methods like wiping or heating. They cut down on waste. No need for rags or extra energy. In a factory, this means faster work and less mess. Qixingyuan focuses on durable designs. Their systems last in wet or dusty spots.

Benefits of Using Air Knives

Why choose an air knife? First, it saves time. Products dry quickly, keeping lines moving. Second, it lowers costs. Less water or dust means fewer fixes later. Third, it’s gentle. No scratches from brushes.

Qixingyuan’s air knives stand out here. They work with blowers for big jobs or compressors for precise ones. Users report better results in cleaning. For example, in electronics, clean boards lead to fewer defects. The systems also handle heat or chemicals. This makes them versatile. You get even air flow every time. That consistency boosts your output.

Factors to Consider When Choosing an Air Knife

Picking the right system isn’t random. Look at your daily tasks. What do you need to achieve? Size, material, and power matter.

Application Requirements

Your job dictates the type. Drying bottles? Need strong air. Cleaning parts? Focus on precision.

- Drying and Water Removal

Water on products causes issues like rust or slips. Air knives blow it off fast. In food lines, this keeps things sanitary. Qixingyuan’s options excel here. Their designs create a strong, uniform blast. Bottles or cans come out dry in seconds. Match the length to your conveyor. Short ones for small items. Longer for wide belts. Think about speed too. High-velocity air handles fast-moving lines. This prevents backups.

- Dust and Debris Removal

Dust sticks to surfaces, ruining quality. An air knife sweeps it away. In PCB making, clean boards are crucial. Qixingyuan provides systems that target fine particles. The air curtain acts like a shield. It blows off chips or powder without harm. Consider the angle. Some setups aim down for falling debris. Others side-blow for even coverage. This keeps your workspace tidy.

Material Selection

Materials affect how long the system lasts. Choose based on your environment. Wet? Go corrosion-proof. Hot? Pick heat-resistant.

These are lightweight and affordable. PVC resists chemicals well. Aluminum is sturdy yet easy to move. Qixingyuan offers both for everyday use. In moist areas, PVC won’t rust. Aluminum suits light-duty lines. They’re simple to install. Lengths adjust to fit your space. For general drying, these work great. They handle moderate pressures without breaking.

For harsh spots, these shine. Stainless steel fights corrosion and heat. Titanium is even tougher, lightweight too. Qixingyuan customizes these. In chemical plants or hot zones, they endure. No warping or cracking. This means less downtime. If your line runs non-stop, invest here. The extra strength pays off over time.

Customization Options

Off-the-shelf might not fit. Customization solves that. Qixingyuan specializes in tailored systems. Need a specific shape? They build it. Provide drawings, and they match. This ensures perfect integration. For unique lines, like curved conveyors, custom rings work best. It boosts efficiency. No gaps in coverage. Plus, it fits your budget. Start with basics, add as needed.

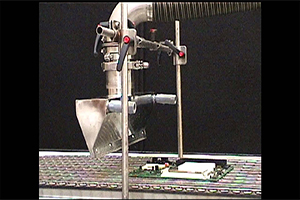

PCB Manufacturing

In PCB manufacturing, maintaining production line cleanliness is absolutely critical for ensuring high-quality outputs. Air knife systems deliver a powerful, focused air stream that efficiently dries circuit boards after washing stages, effectively removing moisture and preventing oxidation or residue buildup. Qixingyuan’s air knives are designed for seamless integration into existing setups, such as etching machines and cleaning stations, guaranteeing consistently flawless surfaces for subsequent processes like plating and soldering.

By adopting these solutions, manufacturers significantly improve product yields and reduce defect rates. The systems also excel at removing dust and particles during pre-assembly phases, preventing potential short circuits. This comprehensive approach minimizes rework, lowers operational costs, and enhances overall production efficiency, allowing companies to maintain a strong competitive edge in the fast-paced electronics industry.

About Shenzhen Qixingyuan Machinery Equipment Co., Ltd.

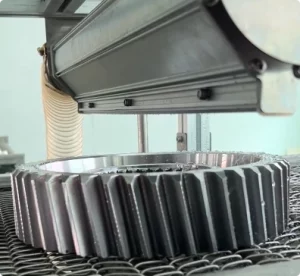

Shenzhen Qixingyuan Machinery Equipment Co., Ltd. stands as a trusted supplier of spares and parts for PCB horizontal line wet processing equipment. Founded in 2011, the company started in Shenzhen’s electronic hub, focusing on circuit board accessories. By 2015, it shifted to making its own products, like air knives, building a strong reputation. Today, it handles research, production, and global sales. Qixingyuan offers a wide array: brush rollers, sponge rollers, rubber rollers, wheels, gears, nozzles, filters, shafts, and more. These fit machines for etching, developing, cleaning, and plating. Materials like PP, PVDF, stainless steel suit wet, corrosive environments. Customization is a big draw—clients get parts tailored to drawings. This ensures smooth fits and long life. The team emphasizes quality and service. They support from design to install. With a global network, Qixingyuan helps factories run better. Their growth shows commitment to innovation and client needs. If you seek reliable parts, they deliver.

Conclusion

Choosing the right air knife system boils down to your needs. Match materials, shapes, and power to your tasks. This leads to better results and savings. Qixingyuan provides solid options. Their focus on durability and customization helps. Invest wisely, and your lines thrive.