Structure and Working Principle

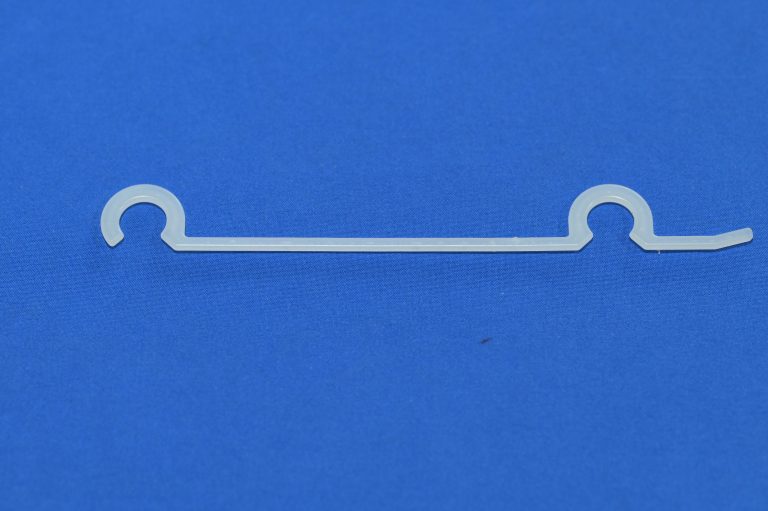

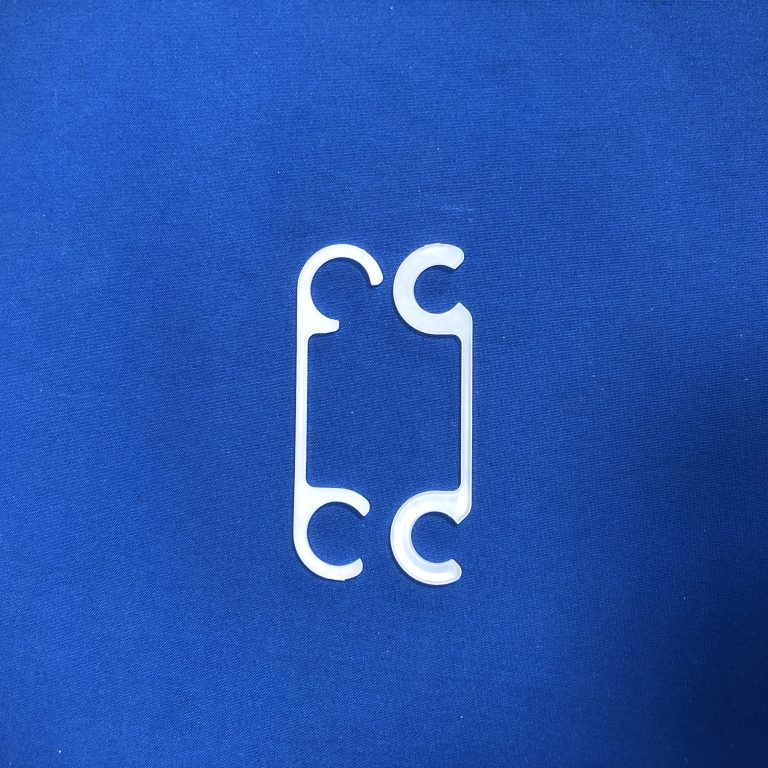

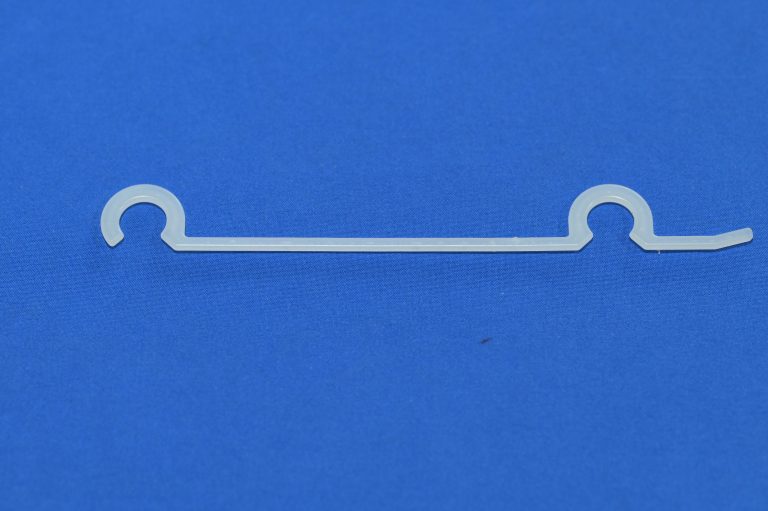

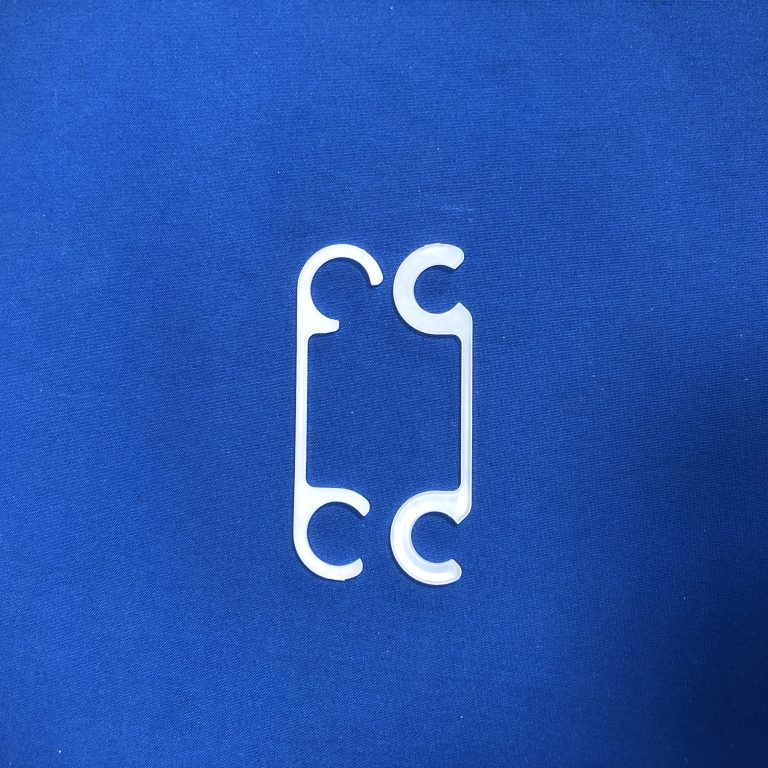

Locking Methods

Common locking methods include self-locking and setscrew types, which utilize clamping or bolting for quick installation and removal.

Mating Parts

Used in conjunction with rollers, spacer sleeves, and other components. Shallow and wide rollers typically require a retaining sleeve, while deep and narrow rollers do not require additional securing.

Mounting Location

Located at the end of the conveyor roller or wheel shaft to limit axial movement of the roller. Main Functions

Prevents roller loosening or axial displacement

Maintains roller concentricity and stability

Simplifies assembly and maintenance, allowing for quick roller replacement

Protective for the conveyor system, preventing PCB deviation due to roller slippage

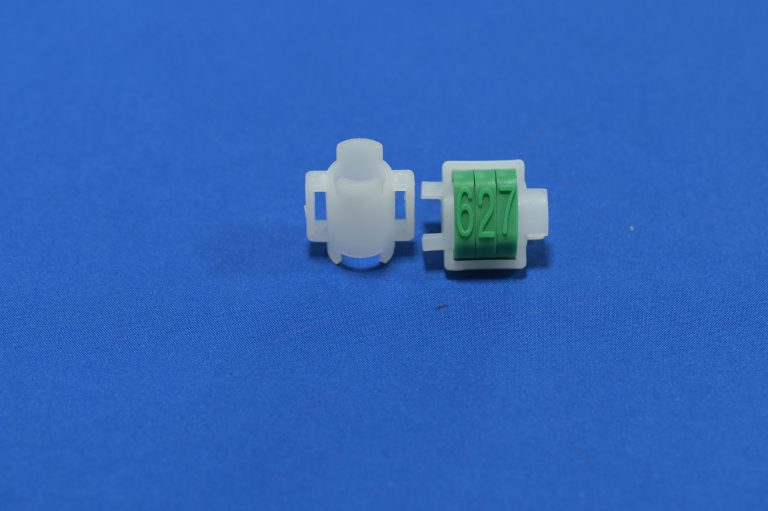

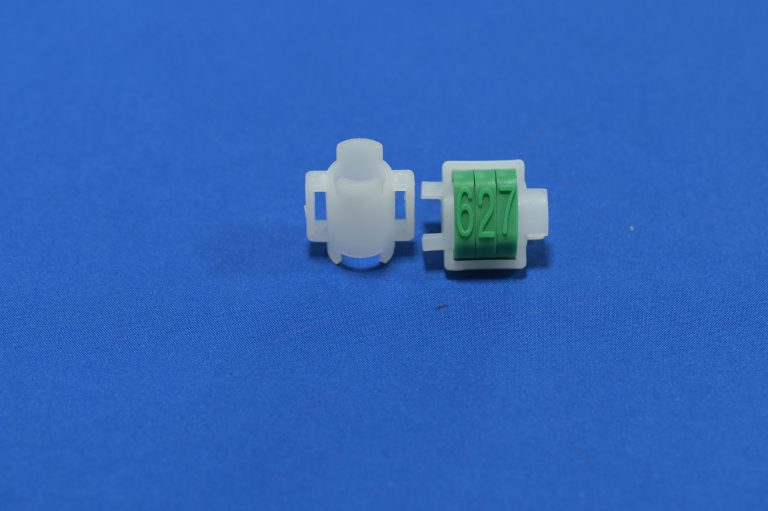

Product Overview

Locking sleeves are mechanical components used in the conveyor system of PCB production equipment. They are primarily used to secure, position, and prevent axial movement or idle rotation of conveyor rollers or wheels during operation. Used in conjunction with rollers, latches, and other components, they stably secure the rollers, ensuring smooth operation during PCB conveying, insertion, or processing.

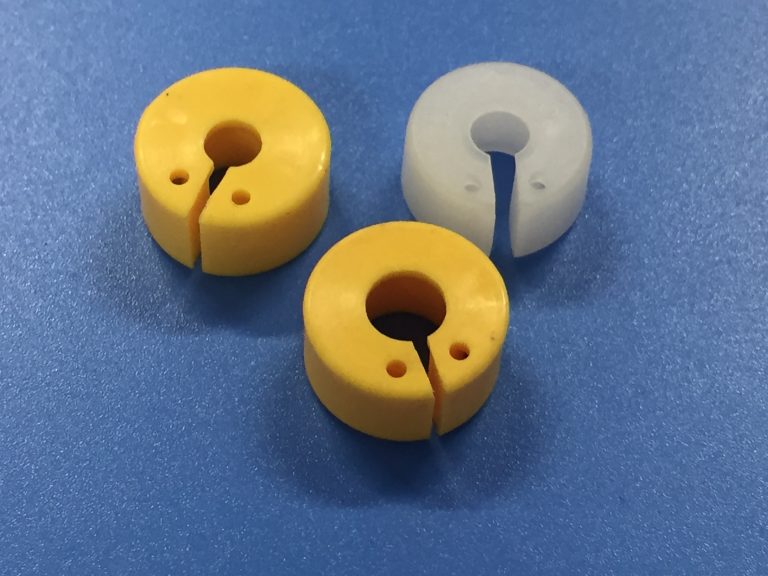

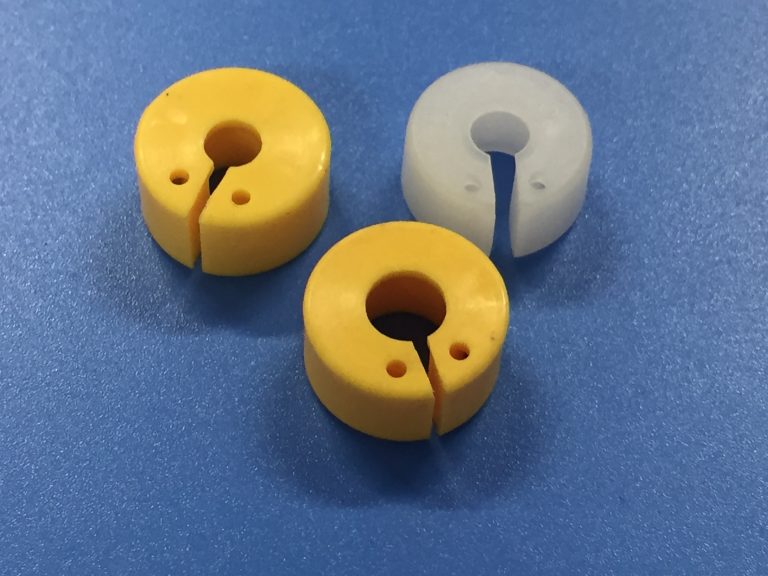

Materials and Specifications

Material: HCPP (high-performance polypropylene); some models can be customized with other engineering plastics or metals upon request

Specifications: Inner diameter must match the roller shaft diameter, and the outer diameter must not exceed the roller outer diameter

Structure: Round, with slots, or other custom shapes

Applications

Conveyor section of PCB production line

Etcher

Developer

De-filming machine

Cleaning machine

Product Advantages

Easy installation and quick maintenance

Lightweight structure reduces equipment load

Wear-resistant and corrosion-resistant, suitable for long-term operation

Compatible with various roller structures

To provide high-precision, high-performance PCB equipment accessories, empowering the global electronics manufacturing industry to achieve efficient production.