Is your equipment transmission not smooth? Are your gears wearing out quickly?

Qixingyuan’s high-precision screws and various gears deliver smooth transmission and lasting durability!

Core Advantages: High-strength materials, precision tooth profile processing, and wear resistance.

Selection Recommendations: Choose the appropriate model and material based on your equipment’s transmission parameters.

Applications: Mechanical transmission systems, drive units, positioning mechanisms.

Stable power output: Ensures precise transmission, reduces maintenance, and extends equipment life.

Function

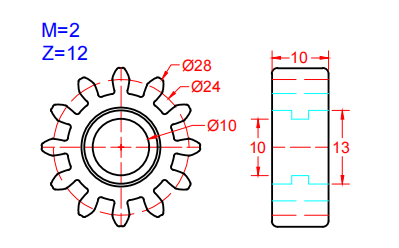

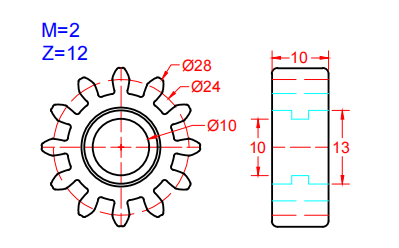

Gears in PCB equipment primarily transmit power from motors or other transmission components to conveyor shafts, enabling synchronized rotation of conveyor rollers or chains. They are typically mounted in pairs on the conveyor shaft to ensure stable and precise conveying of PCBs during production.

Applications

These gears are widely used in PCB production equipment such as etching machines, developers, washers, and dryers, and are particularly suitable for workstations requiring chemical resistance and high transmission accuracy.

Key Advantages

Gears offer high meshing precision, minimal transmission error, and are lightweight. They can operate stably and long-term in chemical environments containing etching solutions and developer solutions, helping to reduce equipment operating loads.

Maintenance Recommendations

Regularly inspect tooth wear and meshing clearance, and replace gears promptly if any abnormalities are found. Maintain shaft alignment during installation to prevent uneven wear. Keep foreign matter out of the meshing area to extend gear life.

To provide high-precision, high-performance PCB equipment accessories, empowering the global electronics manufacturing industry to achieve efficient production.