Picture a busy PCB assembly line. Boards glide through stations, each step precise and timed. At the heart of this flow sits a simple yet vital component: the conveyor roller. These unassuming parts keep everything moving smoothly, from cleaning tanks to drying ovens. In PCB manufacturing, where even a slight snag can halt production, conveyor rollers play a quiet but essential role.

This post dives into what conveyor rollers are, how they function, and why they matter in PCB workflows. We’ll break it down step by step, drawing on real-world insights from the field. Whether you’re troubleshooting a line or just curious about the mechanics, you’ll walk away with a clearer picture. Let’s start with the basics.

What Are Conveyor Rollers?

Conveyor rollers form the backbone of any transport system in manufacturing. They are cylindrical components, often made from durable plastics or composites, that support and propel items along a track. In simple terms, think of them as the wheels under a conveyor belt—rotating to carry loads without friction buildup.

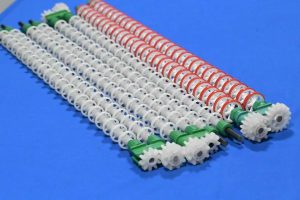

These rollers come in various forms to suit different needs. Some are rigid for heavy-duty tasks, while others flex to cradle sensitive materials. Materials matter here. Engineers often pick from options like polypropylene (PP) for its toughness against chemicals, or polyvinylidene fluoride (PVDF) for extra resistance in harsh environments. Each choice ties back to the demands of the job.

- Hard rollers: Built for stability, these handle straight-line hauls and high speeds. Their solid build prevents wobbling under load.

- Soft or coated rollers: A rubber or polyurethane layer adds grip and cushioning. Ideal when items might slip or scratch.

- Flanged or guided rollers: Edges guide the path, keeping loads centered. Common in tight setups where drift could spell trouble.

No two lines are identical, so rollers adapt. A quick swap can mean the difference between a jammed board and a seamless run. From the factory floor to design specs, these parts blend reliability with versatility.

How Do Conveyor Rollers Work?

At their core, conveyor rollers turn potential energy into motion. A motor or chain drives them, creating rotation that pushes items forward. Friction between the roller surface and the load does the rest—gentle enough not to damage, firm enough to advance.

Let’s unpack the process. First, the roller mounts to a frame via axles or bearings. As power hits, it spins at a set speed, synced to the line’s pace. The load rests on top, transferring weight evenly. This setup minimizes drag, letting boards travel meters per minute without strain.

Basic Mechanics of Rotation

Rotation starts simple. Bearings inside the roller reduce resistance, allowing smooth spins even under pressure. Picture a bike wheel: the hub spins freely, propelled by pedals. Here, it’s similar—gears or belts link to a central drive, timing each roller’s turn.

Load distribution comes next. Weight presses down, but the roller’s curve spreads it out. This prevents hotspots that could warp or wear the part prematurely. In practice, speeds hover around 1-5 meters per minute for PCB lines, balancing throughput with control.

Integration in Conveyor Systems

Rollers don’t work alone. They slot into broader systems—gravity-fed for downhill paths, powered for uphill climbs. Sensors often pair with them, detecting jams or speed dips. Feedback loops adjust on the fly, keeping the rhythm steady.

In a full setup, rollers chain together. End ones might flange to edge the path, while middles focus on support. This teamwork handles curves and inclines, turning a flat line into a dynamic route. Over time, small tweaks—like aligning axles—can cut downtime by half.

Engineers test these interactions rigorously. Simulations show how load shifts affect spin, ensuring no surprises mid-shift. The result? A system that hums along, day in and day out.

The Role of Conveyor Rollers in PCB Manufacturing

PCB production demands precision. Boards, thin and etched with fine circuits, can’t afford mishaps. Enter conveyor rollers: they shuttle these fragile pieces through wet processes, from etching baths to rinse stations. Without them, the line grinds to a halt.

In this high-stakes world, rollers must juggle speed and care. They carry boards weighing grams yet spanning feet, all while dodging chemicals and heat. A well-placed set keeps everything aligned, cutting defects that cost time and money.

Navigating Wet Processing Lines

Wet lines—think developers and etchers—expose rollers to acids and solvents. Here, corrosion-resistant models shine. They roll boards through tanks, where immersion cleans or patterns circuits. Rollers emerge dripping but unbowed, their coatings repelling residue.

Take a typical etch station. Boards enter submerged, then lift via rollers to drain. The motion must be even; uneven pulls could streak patterns or chip edges. Rollers with low-friction surfaces excel, letting gravity assist while maintaining grip.

Data backs this up. Lines with upgraded rollers see 15-20% fewer board drops. It’s not magic—just smart design meeting real needs.

Handling Delicate Boards Without Damage

PCBs aren’t bricks. They’re layered composites, prone to bends or cracks. Soft rollers step in here, their yielding surfaces absorbing jolts. During flips or transfers, they cushion impacts that rigid parts might amplify.

Precision counts too. Flanged rollers guide edges, preventing sideways slips in narrow tracks. This keeps boards centered, vital for downstream steps like soldering. One misalignment, and yields plummet.

To compare, here’s a quick look at roller types in action:

| Roller Type | Best For | Key Benefit in PCB Lines | Potential Drawback |

| Hard Plastic | High-speed straight runs | Stable, fast throughput | Less forgiving on thin boards |

| Rubber-Coated | Transfer zones | Grip reduces slips | Wears faster in chemicals |

| Flanged Guide | Edged paths | Keeps alignment tight | Needs precise installation |

This table highlights trade-offs. Pick wrong, and issues mount. Pick right, and the line flows like clockwork.

Beyond the board, rollers influence the big picture. They tie into automation, syncing with robots for seamless handoffs. In cleanrooms, their smooth finishes cut particle shedding, upholding air quality. It’s a chain reaction: better rollers mean fewer stops, happier crews, and stronger output.

Maintenance and Best Practices for Longevity

Rollers last years with care, but neglect shortens that. Dust buildup or chemical soak invites wear. Regular checks spot cracks early, averting breakdowns.

Start with visuals. Scan for gouges or uneven wear—signs of overload. Then, spin tests: a free roll should hum quietly, no grinds. Clean with mild solutions; harsh scrubs strip coatings.

- Inspect monthly: Look at bearings for play or noise.

- Lubricate sparingly: Just enough to ease friction, avoiding gunk.

- Align yearly: Missteps cause uneven loads, speeding fatigue.

- Track usage: Log hours to predict swaps before failures hit.

These habits pay off. A tuned line runs cooler, quieter, boosting morale on the floor. Operators notice; they trust gear that doesn’t fight back.

For deeper dives, log patterns. If one zone wears fast, tweak speeds or loads. It’s proactive, not reactive—turning maintenance into a strength.

About Shenzhen Qixingyuan Machinery Equipment Co., Ltd.

Shenzhen Qixingyuan Machinery Equipment Co., Ltd. stands as a dedicated supplier of spares and parts for PCB horizontal line wet processing equipment. Founded in 2011, the company has grown from a modest trading outfit into a full-spectrum provider, blending sales with in-house R&D. Today, it crafts everything from custom rollers to filtration systems, all tailored for the rigors of etching, developing, and rinsing stations.

What sets Qixingyuan apart is its focus on practical solutions. Engineers here draw from years of floor-level know-how, ensuring parts fit real workflows—not just blueprints. Materials like corrosion-proof plastics and high-grip coatings reflect that grit. Clients span global lines, from startups scaling up to veterans fine-tuning yields.

Beyond products, Qixingyuan builds ties. Quick-turn customs, reliable stock, and hands-on support turn one-off buys into partnerships. It’s about easing the daily grind, letting teams chase bigger goals. In a field where downtime bites, this approach delivers quiet wins—steady runs, sharp edges, and peace of mind. With roots in Shenzhen’s tech hub, the firm eyes forward, ready to shape tomorrow’s lines.

Conclusion

Conveyor rollers might seem like background players, but in PCB manufacturing, they steal the show. From steadying fragile boards to powering wet-line flows, their work keeps production on track. We’ve seen how their mechanics blend simplicity with smarts, adapting to demands that never quit.

As lines grow complex, these parts evolve too—tougher materials, smarter designs. The payoff? Smoother ops, fewer headaches, and boards that hit specs every time. Next time you watch a line hum, tip your hat to the rollers underneath.