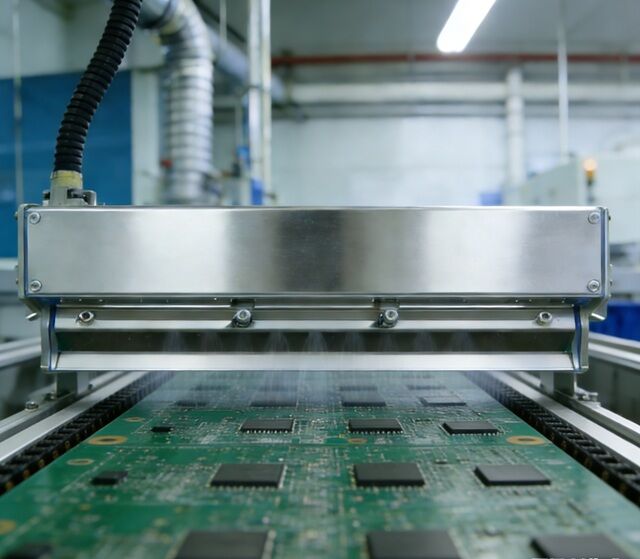

In modern PCB fabrication, the PCB developing process is where circuit patterns are either defined clearly or quietly damaged. After exposure, the photoresist must be removed in unexposed areas with tight control over spray pressure, chemistry, and coverage. Any instability at this stage can lead to undercut traces, residual resist, or uneven line width. These defects are difficult to fix later and often result in scrap.

What many factories discover over time is that developing quality does not rely on chemistry alone. Spray nozzles, pipe layout, filtration systems, and even liquid-blocking rollers all influence how uniformly the developer reaches the board surface. Fine-tuning these accessories is often the fastest way to improve consistency without slowing the line.

Why the PCB Developing Process Demands High-Precision Parts

Before looking at individual components, it helps to understand why the PCB developing process is so sensitive to mechanical details.

Fine Lines Mean Narrow Process Windows

As line width drops below 75 microns, the tolerance for spray force and flow variation becomes very small. If pressure is slightly high, resist on narrow traces can lift. If too low, unexposed resist may remain in pads or between fine lines. In high-density interconnect production, even a small spray shadow caused by a worn nozzle can create a pattern defect across multiple panels.

The developing stage also deals with partially softened photoresist, which is more fragile than fully cured coatings. Turbulence or uneven jet impact can damage features that looked perfect after exposure.

Interaction Between Mechanics and Chemistry

Developer concentration and temperature are usually well controlled. However, if spray distribution is uneven, chemical action becomes uneven as well. Some areas receive fresh solution at the correct velocity, while others are washed by slower, partly spent liquid. This creates local over-development and under-development on the same panel.

Improving the hardware side of the PCB developing process allows chemical control systems to work as intended. Qixingyuan supplies a wide range of spray and liquid-handling accessories used in horizontal PCB lines, helping manufacturers maintain stable and repeatable developing conditions.

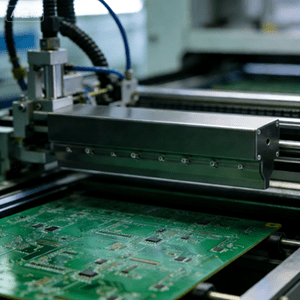

Spray Nozzles and Spray Bar Design

The spray system is the heart of the PCB developing process. Its job is to deliver developer evenly across the entire board surface at a controlled impact force.

Choosing the Right Nozzle Type

Fan spray and cone spray nozzles are commonly used in PCB developing machines. Fan spray types create a flat, uniform sheet that overlaps with adjacent sprays, while cone sprays provide more concentrated impact for stubborn resist in fine areas. The choice depends on board design and line speed.

Material also matters. In alkaline developer environments, plastics such as PP or PVDF resist corrosion and reduce particle shedding. Stainless options may be selected for higher mechanical strength in some systems. Anti-clog nozzle designs with smooth internal channels help maintain stable flow over long production runs.

The table below compares typical nozzle features in the PCB developing process.

| Nozzle Type | Spray Pattern | Best Use | Maintenance Frequency |

| Fan Spray | Flat sheet | General developing, wide panels | Medium |

| Full Cone | Circular | Fine features, via areas | Medium to high |

| Hollow Cone | Ring-shaped | Edge areas, gentle rinsing | Low to medium |

| Solid Jet | Straight stream | Spot cleaning, special zones | Low |

Correct overlap angle between nozzles is equally important. Gaps in coverage may not be visible to the eye but can leave faint resist residue that later affects etching.

At the end of each spray section, Qixingyuan provides corrosion-resistant spray nozzles, spray pipes, and connectors tailored for PCB developing lines, helping customers maintain uniform spray coverage and reduce clogging-related downtime.

Preventing Clogging and Flow Instability

Nozzle blockage is one of the most common hidden causes of variation in the PCB developing process.

Sources of Particles in Developing Lines

Photoresist fragments, copper fines from upstream processes, and scale from pipes can all enter the spray system. Even small particles can partially block a nozzle or change its spray angle. In a line running thousands of panels per shift, this leads to gradual drift in developing performance.

Without proper filtration, operators often react only after visible defects appear. By that time, many panels may already be affected.

Filtration Strategy for Stable Spray

Installing multi-stage filtration in the developer circulation loop is a practical solution. A coarse filter captures larger debris, while a fine filter protects nozzles from small particles. Filter pore sizes between 5 and 20 microns are common, depending on line design.

Easy-to-replace filter cartridges reduce maintenance time and encourage regular service. Monitoring pressure drop across filters also helps predict when replacement is needed, rather than waiting for spray performance to change.

To support stable flow in the PCB developing process, Qixingyuan offers filter housings, filter elements, and liquid circulation accessories designed for chemical resistance and convenient maintenance in horizontal wet process equipment.

Spray Pressure, Piping, and Distribution Uniformity

Even with good nozzles and filters, the PCB developing process can suffer if liquid distribution inside the machine is not balanced.

Pressure Balance Across the Width

In wide panels, pressure loss along the spray bar can cause stronger spray at the inlet side and weaker spray at the far end. This may create slight differences in developing across the panel width. Using properly sized pipes and balanced feed points helps keep pressure uniform.

Flow meters and pressure gauges placed at key positions give operators a real picture of system stability. When values drift from normal ranges, maintenance can be scheduled before defects appear.

Pipe Material and Chemical Compatibility

Developer solutions are often alkaline and warm. Over time, incompatible materials may degrade, shedding particles into the system or changing internal diameter. Selecting corrosion-resistant pipes and connectors reduces this risk and keeps the PCB developing process cleaner.

Attention to piping details may not seem as important as chemistry, but in practice it often makes the difference between a line that needs frequent adjustment and one that runs smoothly for months. Qixingyuan supplies spray pipes, connectors, and fluid control components compatible with common PCB developing chemistries, supporting even liquid distribution throughout the equipment.

Edge Control and Splash Management

During the PCB developing process, liquid does not always stay where it should. Splashing and backflow can disturb spray patterns and contaminate nearby sections.

Role of Water-Blocking and Guide Rollers

Rubber or plastic rollers placed along the sides of the conveyor help contain developer and guide panels steadily through the spray zone. If these parts wear or deform, panels may vibrate or shift slightly, changing how spray hits the surface.

Edge-control components also reduce chemical carryover to adjacent chambers. This helps keep rinse and developing sections more stable, which is especially important in high-precision lines.

Regular inspection of these mechanical parts prevents many subtle process issues. Qixingyuan provides chemical-resistant rubber rollers and guide components used near spray and developing zones, helping factories maintain clean separation between process stages.

About Shenzhen Qixingyuan Machinery Equipment Co., Ltd.

Shenzhen Qixingyuan Machinery Equipment Co., Ltd. focuses on spare parts and accessories for PCB horizontal wet processing lines. Its product portfolio covers spray nozzles, spray pipes, filtration systems, rollers, gears, transmission parts, and other functional components used in developing, etching, rinsing, and cleaning equipment. With experience in chemical environments and high-speed lines, the company supports customers looking for reliable replacement parts and customized solutions.

Conclusion

The PCB developing process depends on more than chemical formulas. Spray nozzles, filtration, piping balance, and edge-control parts all shape how evenly the developer interacts with the board. By selecting well-designed accessories and maintaining them properly, manufacturers can reduce line width variation, prevent resist residue, and improve yield without slowing production. Stable hardware builds a stable process, which is the foundation of consistent PCB quality.