LCD Cleaning

[ industry background t]

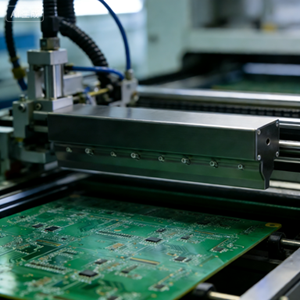

LCD modules, touch glass, and polarizers demand exceptionally high cleanliness. Their optical surfaces are prone to defects caused by dust, fibers, or static electricity, which may result in bright spots, dark spots, or poor adhesion—directly affecting product quality.

[Common pain pointst]

- The electrostatic adsorption of dust is serious → the ordinary cleaning method is difficult to completely remove.

- Scratching or scraping the surface with abrasive materials → causing irreversible damage.

- Short lifespan of cleaning tools → High costs.

- Short filter cartridge lifespan and frequent clogging lead to inconsistent water purification quality.

[Our solution]

Qixingyuan provides high-cleanliness-grade, long-lasting, and anti-static cleaning consumables compatible with various LCD production line cleaning systems.

[Available productst]

-Anti-static cotton cloth / dust-free cloth

-Clean the rubber roller / roll cleaning cloth

-Filter element / filter mesh

-Nozzle, nozzle fitting

-Special rubber wheels and rubber-coated wheels are used for cleaning equipment.

[Application effect]

– Significantly reduce surface defects such as highlights and shadows.

-Reduce static electricity adsorption issues

-Extended lifespan of cleaning supplies

-Improve the stability of optical surfaces

[Industry Scenario Example]

-Cleaning of LCD modules before bonding

-Dust removal before attaching the polarizer

-Cleaning of glass substrates and dust-free wiping

-Electrostatic cleaning process for the bonding section