In PCB manufacturing, drying processes play a key part in maintaining quality. Air knives stand out as tools that handle moisture removal with precision. They direct high-speed air streams to clear water from circuit boards after cleaning or etching stages. This approach cuts down on defects like oxidation or residue buildup. Specifically, using an air knife to reduce PCB oxidation effectively minimizes surface exposure to moisture, a primary cause of corrosion. Factories using these systems often see fewer rework needs. Shenzhen Qixingyuan Machinery Equipment Co., Ltd. (Qixingyuan), a specialist in PCB equipment parts and a leading China air knife supplier for PCB manufacturing, supplies air knives that fit seamlessly into production lines, helping firms keep output steady and costs low.

Understanding Air Knives in Electronics Production

Air knives create a thin, focused sheet of air. Compressed air or blower systems power them. In electronics, they dry surfaces without contact, avoiding scratches on delicate boards.

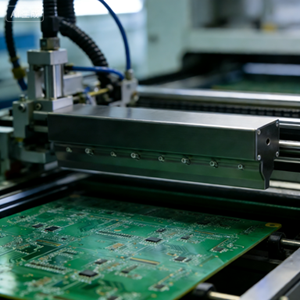

How Air Knives Work in PCB Wet Processing Drying

Wet processes in PCB production involve rinsing boards with chemicals or water. Leftover droplets can cause shorts or corrosion. An air knife drying system blasts air at velocities up to 200 mph, shearing off water in seconds. Boards move through conveyor lines, and the air curtain evaporates or pushes moisture away. Installing an air knife for PCB conveyor line ensures continuous, in-line drying without disrupting the flow. This step comes right after rinsing in etching or developing machines.

Such systems replace older methods like hot air ovens, which use more energy. In a typical setup, air knives mount above and below conveyors. They adjust for board thickness, ensuring even drying. Production lines running at 5-10 meters per minute benefit from this quick action, reducing bottlenecks.

Key Components of an Air Knife Setup

An effective setup includes the knife body, air source, and mounting brackets. The body, often made from durable materials like stainless steel, shapes the air flow. Blowers or compressors supply the pressure. Qixingyuan air knives for PCB wet processing have excellent resistance to corrosion in humid environments, which extends the lifespan of printed circuit board wet processing lines.

Advantages of Using Air Knives for Circuit Board Drying

Drying impacts yield rates directly. Air knives bring clear gains in speed and reliability. They handle high volumes without slowing lines.

Improved Efficiency and Speed

Traditional drying might take minutes per board. Air knife in PCB manufacturing cuts that to seconds. In facilities producing thousands of boards daily, this adds up. One case from an Asian electronics plant showed a 30% throughput increase after switching to a high-efficiency air knife for PCB drying. Energy use dropped too, as blowers consume less power than heaters.

Boards dry uniformly, preventing spots that lead to failures in soldering or coating. This consistency supports faster assembly downstream.

Cost Savings in Operations

Lower energy bills stand out. Heat-based dryers run constantly, while air knives activate only when needed. Maintenance stays simple—clean nozzles periodically. Qixingyuan’s designs use modular parts, making replacements quick and cheap.

Fewer defects mean less scrap. Industry reports note reject rates falling from 5% to under 1% with proper drying. Over a year, that saves thousands in materials.

Enhanced Product Quality

Moisture left on boards invites issues like delamination during reflow. Benefits of air knives in electronics include spotless surfaces ready for next steps. No physical contact means no marks or static buildup, crucial for fine-pitch components.

In cleanrooms, air knives filter air to avoid contamination. This aligns with standards like IPC for PCB quality.

Air knives adapt to various board sizes. Adjustable slots handle everything from small mobile PCBs to large panels. This flexibility suits diverse production runs.

Applications of Air Knives in PCB Wet Processing

Wet processing covers several stages where air knives shine. For reliable performance in the harsh chemical environments, a corrosion-resistant air knife for PCB etching is essential.

In Etching and Developing Machines

After etching, boards rinse to remove chemicals. PCB drying solutions like air knives blow off residues here. This prevents carryover that could etch unevenly.

Developing removes photoresist. Quick drying stops reactions, preserving patterns. Lines with air knives maintain sharp features down to 50 microns.

Post-Cleaning and Rinsing Stages

Cleaning strips flux or contaminants. Rinsing follows, but water spots form if not dried fast. Air knives create a barrier, forcing water into drains.

In multi-stage rinses, they separate sections, reducing chemical mixing. This keeps baths pure longer, cutting reagent costs.

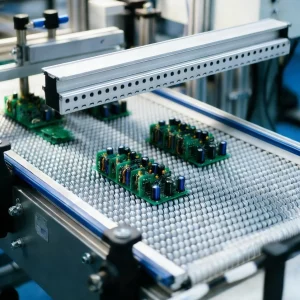

Integration with Conveyor Systems

Conveyors move boards through processes. Air knives mount inline, syncing with speeds. Sensors trigger them for energy savings.

Qixingyuan provides kits that bolt onto existing lines, easing upgrades. Factories report smoother operations without major overhauls.

Challenges and Solutions of Air Knives in PCB Manufacturing

Noise can arise from high velocities. Modern designs incorporate silencers, dropping levels below 80 dB.

Air quality matters—filters prevent clogs. Regular checks keep performance steady.

Initial setup requires tuning for air pressure. Too low leaves moisture; too high wastes energy. Testing with sample boards finds the sweet spot.

Materials resist chemicals in PCB environments. Stainless or coated knives last years in acidic settings.

About Shenzhen Qixingyuan Machinery Equipment Co., Ltd.

Shenzhen Qixingyuan Machinery Equipment Co., Ltd. serves as a key supplier of spares and parts for PCB horizontal line wet processing equipment. Founded in 2011 as a trading firm, it grew into manufacturing by 2015, launching its own air knife series. By 2022, the company expanded globally, focusing on foreign trade. Products include brush rollers, sponge rollers, gears, nozzles, filters, and more, all tailored for machines like etchers, developers, and cleaners. Materials range from PP and PVDF to stainless steel, ensuring durability in corrosive settings.

Qixingyuan emphasizes customization. Clients get parts matched to their line specs, with customizable in interface type (G1/4, G1/2), length, and air gap width. The firm supports various payment methods, including T/T, and trade terms like EXW or FOB. Working hours run Monday to Friday, 8 AM to 6 PM, excluding Chinese holidays. With a focus on quality, the company helps factories cut downtime and boost yields. Visit qxymachinery.com for details on applications in PCB production, or contact for custom quotes. Their air knives and accessories keep lines running smoothly worldwide.

Conclusion

Air knives transform drying in PCB manufacturing. They deliver fast, even results that cut costs and lift quality. As lines push for higher speeds, these tools prove essential. Factories adopting them see real gains in output and reliability. Looking ahead, advancements in air flow tech will refine them further.