In the fast-paced world of electronics, manufacturers face constant pressure to deliver high-quality printed circuit boards faster and at lower costs. A well-designed PCB manufacturing production line plays a key role in meeting these demands. It streamlines processes from fabrication to assembly, cutting down on waste and downtime. This setup not only speeds up output but also maintains consistent quality across batches.

Companies like Shenzhen Qixingyuan Machinery Equipment Co., Ltd. ( Qixingyuan) provide essential spares and parts that support these lines, such as air knives and conveyor rollers, which help keep operations smooth. Drawing from industry practices, this article explores how such lines drive better results in real manufacturing settings.

Key Components of a PCB Production Line

A typical PCB production line includes several interconnected stages that work together for seamless flow. These range from initial material handling to final testing.

Fabrication Stage Essentials

At the start, raw materials like copper-clad laminates go through drilling, etching, and plating. Here, precision tools ensure holes align perfectly, avoiding costly rework. For instance, in high-volume runs, automated drillers handle thousands of holes per panel, reducing manual errors.

Wet processing equipment is vital in this phase. Qixingyuan supplies durable seal strips and spray systems that prevent leaks and maintain chemical balance during etching. Such parts extend machine life and cut maintenance stops.

Moving from fabrication, the line shifts to assembly, where components get placed on boards.

Assembly and Soldering Processes

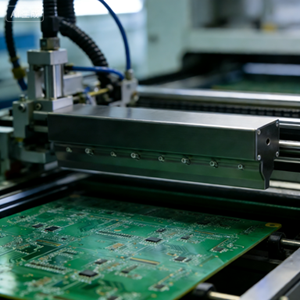

Surface mount technology (SMT) lines dominate assembly, with pick-and-place machines positioning parts at high speeds. These systems can place up to 50,000 components per hour in optimized setups.

Reflow ovens then solder everything in place. Proper temperature control avoids defects like cold joints. Qixingyuan’s measurement and control products help monitor these conditions, ensuring steady performance.

This leads into inspection, where automated optical systems catch issues early.

Benefits of an Integrated Production Line

An integrated PCB manufacturing production line brings clear gains in speed and resource use. Factories see measurable improvements when all parts sync up.

Reduced Downtime and Faster Throughput

Downtime eats into profits. A streamlined line minimizes it by automating transitions between stages. For example, conveyor systems move boards without pauses, boosting throughput by 20-30% in many facilities.

Qixingyuan’s transmission systems and bushings add reliability here. Their high-purity materials resist wear, leading to fewer breakdowns. In one case from PCB blowing and drying applications, high-precision air knife for PCB drying shortened cycle times, allowing more boards per shift.

Beyond speed, these lines cut material losses.

Cost Savings Through Waste Reduction

Waste from defects or excess materials adds up. PCB panelization groups multiple boards on one sheet, maximizing laminate use. This method can save 15-20% on materials, as seen in standard 18×24-inch panels fitting 25 small boards.

Tab routing or V-scoring makes separation easy post-assembly. Qixingyuan’s gears and screws support precise panel handling, reducing scrap from misalignment.

Such efficiencies tie into overall quality.

Improved Quality and Consistency

Consistent output builds trust with clients. Automated lines apply the same standards to every board, lowering defect rates to under 1% in top setups.

In developing (post-etching), customized parts from Qixingyuan adapt to specific needs, handling non-standard boards without quality dips. This consistency supports industries like automotive, where reliability is non-negotiable.

Strategies for Enhancing Line Efficiency

To get the most from a PCB manufacturing production line, factories adopt proven tactics. These focus on layout, tech upgrades, and staff training.

Optimizing Layout and Workflow

A smart layout cuts travel time for boards. Place machines in sequence: drilling near etching, then to assembly. This linear flow can shave 10-15% off production time.

Incorporate rails and fiducials for alignment. PCB panelization benefits shine here, with 2-3mm clearances preventing edge damage during conveyor moves.

Qixingyuan’s water retaining rollers fit into these setups, keeping fluids contained and floors dry for safer, faster workflows.

From layout, attention turns to technology.

Adopting Automation and Monitoring Tools

Automation handles repetitive tasks. Robotic arms in SMT lines place tiny components with 0.01mm accuracy, far beyond manual work.

Real-time monitoring spots issues like temperature drifts. Qixingyuan’s consumables and control products integrate with these systems, providing data for quick adjustments.

This tech focus extends to maintenance for wet processing equipment.

Regular Maintenance and Upgrades

Scheduled checks prevent surprises. Clean gears and replace worn bushings quarterly to avoid halts.

Upgrading to durable parts pays off. In PCB transmission systems, Qixingyuan’s offerings lower failure rates, supporting 24-hour runs with minimal stops.

Real-World Applications and Results

In practice, these strategies yield strong outcomes. After integrating a full automated PCB assembly line with panelization, output rose 25%, and costs dropped due to less waste.

High-mix environments shows how flexible parts like spray cleaners from Qixingyuan handle varied board types, maintaining efficiency across short runs.

Tables help illustrate gains:

| Metric | Before Optimization | After Optimization |

|---|---|---|

| Throughput (boards/hour) | 200 | 260 |

| Defect Rate (%) | 2.5 | 0.8 |

| Material Waste (%) | 18 | 12 |

Bullet points highlight quick wins:

- Use V-scoring for easy depaneling.

- Add tooling holes for precise machine grips.

- Monitor with sensors to catch variances early.

These steps make lines more responsive.

About Shenzhen Qixingyuan Machinery Equipment Co., Ltd.

Shenzhen Qixingyuan Machinery Equipment Co., Ltd. stands as a leading supplier of PCB horizontal line wet processing equipment spares and parts. Founded in 2008, this high-tech enterprise blends design, production, and sales to deliver reliable solutions for the electronics industry. Based in Baoan District, Shenzhen, the company holds multiple national patents, underscoring its focus on innovation in wet processing tech.

Qixingyuan specializes in items like air knives, seal strips, conveyor rollers, gears, screws, spray and cleaning products, transmission systems, bushings, consumables, and measurement tools. These parts boost durability and cut downtime in PCB lines. For instance, their high-purity materials in air knives reduce failure rates, while customizable in interface type (G1/4, G1/2), length, and air gap width.

The company’s philosophy centers on quality, customer satisfaction, integrity, and mutual success. It provides 24-hour technical support, ensuring quick fixes for issues in blowing, drying, or developing processes. This approach empowers manufacturers worldwide to achieve efficient production. With a vision to lead in smart manufacturing, Qixingyuan drives progress in PCB equipment accessories.

Contact them at their Shenzhen address or via WhatsApp for inquiries on parts that enhance line performance. Their expertise helps factories scale up reliably.

Conclusion

A strong PCB manufacturing production line transforms operations by speeding up processes, trimming costs, and upholding quality. From panelization to automation, these elements work together for better results. Manufacturers who invest in solid setups and reliable parts see lasting gains in a competitive field.

FAQs

What role does automation play in boosting efficiency in PCB manufacturing?

Automation in PCB lines handles tasks like component placement and soldering with speed and precision. Pick-and-place machines manage high volumes without fatigue, cutting assembly time by 30-40%. This leads to fewer errors and higher yields.

For wet processing, automated controls from suppliers like Qixingyuan maintain chemical levels, preventing defects. Factories report smoother runs and quicker market delivery. If you’re scaling production, consider Qixingyuan’s transmission parts—they integrate seamlessly to keep lines running non-stop, potentially increasing your output while lowering costs. Reach out for tailored advice on automating your setup.

How does PCB panelization improve production line performance?

PCB panelization groups boards on one sheet for batch handling, slashing setup times and material use. It fits automated lines better, with methods like tab routing allowing easy separation. Yields improve by 15-20%, as uniform panels reduce handling damage. In assembly, this means faster throughput in reflow ovens.

Qixingyuan’s rollers and gears support precise panel movement, minimizing jams. Manufacturers using this see cost drops and quality rises.

For your operations, explore Qixingyuan’s customizable spares—they enhance panel stability, making high-volume runs more profitable. Contact them to discuss how these fit your line.

How can improving PCB assembly speed impact overall business growth?

Faster assembly means quicker product launches, capturing market share. Lines with optimized flows deliver 25-35% more boards daily, scaling orders without extra staff. Reduced defects build client loyalty.

Qixingyuan’s control products fine-tune processes for this speed. In real scenarios, upgraded lines double revenue in a year. It frees resources for innovation. For growth, pair with reliable parts like their spray systems. These ensure smooth operations.

If expansion is your goal, Qixingyuan’s expertise in wet processing spares supports it. Reach their Shenzhen team to explore options that drive your business forward.