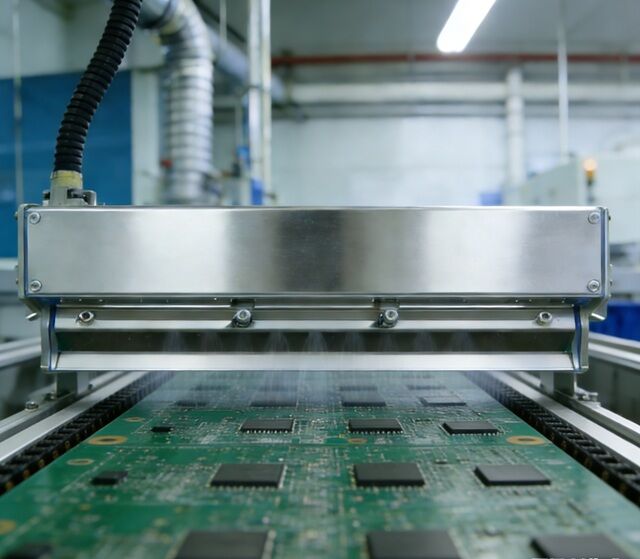

PCB making is a very detailed process. The cleaning step plays a key role in making sure the final item is good and steady. In the cleaning part, every small thing counts. This includes taking away dirt and dealing with oxidation layers in the right way. Picking the correct spare parts is important to get the best results in this step. This piece looks at main items like brush rollers, sponge rollers, and filtration systems. These help make a clean PCB surface. They also boost later steps and speed up the work.

The Importance of Cleaning in PCB Manufacturing

In PCB making, cleaning is not just an extra task. It is a must to make sure the end product works well and lasts. The cleaning step gets rid of bad stuff like dust, oils, oxides, and leftovers from earlier parts. If these stay, they can cause big problems in the PCB. Dirt can mess up how solder sticks. It can lead to weak electrical links. In bad cases, it can make the whole circuit fail.

So, making the cleaning step better is vital. You do this with good spare parts that are kept up well. This helps speed up making and cut down on mistakes.

Key Spare Parts in the PCB Cleaning Process

Many parts help a PCB cleaning line run well. You need to pick these parts with care. Keep them in good shape. Sometimes, change them to fit your line’s needs. Let’s look closer at the main spare parts in PCB cleaning.

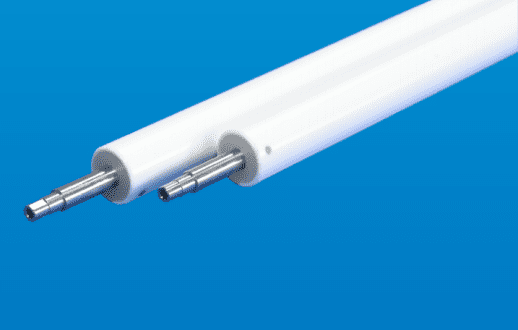

Brush Rollers

Brush rollers are common in PCB cleaning setups. They take away dirt, bad stuff, and oxidation layers from the board top. These rollers have different setups. They include high-density brush filaments. These give a good scrubbing without hurting the soft PCB surface.

Core Advantages:

High-density brush filaments offer a firm cleaning move.

The bendy bristles make sure the PCB top stays safe.

Different stuff like nylon and non-woven fabric fit various cleaning jobs.

By choosing the right brush roller for cleaning, PCB makers can boost how well it cleans. They cut down oxidation speed. They raise success in later plating and printing steps. Good brush rollers from brands like Qixingyuan give exact cleaning fixes. They help keep high clean standards. They also make gear last longer.

Qixingyuan provides custom brush rollers with great wear resistance and bendiness. Their items work well for PCB pre-treatment and pre-etching cleaning. They make sure dirt and oxide go away fully.

Sponge Rollers

Sponge rollers are another main part in PCB cleaning. These rollers take out leftover water from the board. They make sure the PCB top is fully dry before the next step. Too much water can cause oxidation. It can mess with later making steps.

Core Advantages:

Great at soaking up water.

Soft material that does not shed keeps the PCB safe.

Long use time and strong against wear.

By picking the right sponge roller for line speed and roller gaps, makers can dry faster. They use less energy. They make drying better overall. This leads to easy making and good results in later parts.

Qixingyuan’s sponge rollers come from special polymer stuff with strong water pull. They come in many sizes. You can change them for different needs. They give great drying speed in PCB making.

Filtration Systems

Filtration systems are key in the cleaning step. They filter out bad bits from the cleaning liquid. This makes sure the PCB top does not get dirty again. Good filtration stops bad particles from building up. These could block the system or make cleaned PCBs worse.

Core Advantages:

High-precision filtration keeps liquid flow clean and even.

Designs that fight rust and high pressure make the system last.

You can change them to fit various PCB wet processing setups.

Filters kept well lower the chance of dirt coming back to the PCB top. They make the process steady. They cut down how often you fix the whole cleaning setup. Putting money into good filtration parts is a must to make work run at its best in PCB making.

Qixingyuan’s filtration components give exact filtering. They are made to handle high pressure and rust spots. They work well for cleaning liquid, solvent, and paint flow systems. They help keep the cleaning step fast and good.

The Role of Maintenance in Spare Part Efficiency

Each PCB making line has its own needs. Solutions that fit all may not work best. Changing spare parts like brush rollers, sponge rollers, and filters can make a big change. They boost cleaning speed and raise overall making quality.

For example, changing brush rollers to match line speeds and board dirt levels can make cleaning much better. In the same way, picking the right filtration setup based on liquid types and particle size is key for best results.

Keeping spare parts in the cleaning step is as important as picking the right ones. Regular fixes make sure all parts work at top level. They stop problems like blocks, bad cleaning, or gear breaks. These could slow the making process.

Meet Shenzhen Qixingyuan Machinery Equipment Co., Ltd.,

Shenzhen Qixingyuan Machinery Equipment Co., Ltd., is a top seller of PCB horizontal line wet processing equipment spares and parts. They offer many good items that fit PCB makers’ needs. Their products aim to boost cleaning speed, cut stop time, and make gear last. Qixingyuan is the helper you need for best making results.

Shenzhen Qixingyuan Machinery Equipment Co., Ltd., gives strong after-sales help. This makes sure all spare parts work well over time. This includes brush rollers, sponge rollers, and filtration components. With their easy-to-put-in, rust-proof products, PCB makers can cut down stop time. They keep lines running smooth.

Conclusion

Making spare parts better in the PCB cleaning process is a must. It speeds up making and makes sure the end item is good. By picking good, changed parts like brush rollers, sponge rollers, and filtration systems, PCB makers can raise cleaning work. They cut down mistakes. They boost how work runs.

1. What are the benefits of using high-density brush rollers in PCB cleaning?

High-density brush rollers offer a more effective cleaning action by using densely packed filaments, which help remove contaminants, oxidation, and residues from PCB surfaces. These brushes ensure a thorough cleaning process without damaging the delicate PCB surface. Their design improves electroplating adhesion and reduces defects. Additionally, high-density brushes increase cleaning efficiency, leading to fewer reworks and enhanced production quality by maintaining consistent results across production runs.

2. How can sponge rollers help in the drying stage of PCB manufacturing?

Sponge rollers efficiently remove residual moisture from PCBs after the cleaning process. With their strong absorption capacity, they help prevent oxidation and ensure a completely dry surface, which is essential for the subsequent production stages. By using sponge rollers, manufacturers improve drying efficiency, reduce energy costs, and prevent moisture-related defects. Additionally, they provide consistent performance, even at high speeds, ensuring smooth operations and preventing potential production delays due to moisture issues.

3. Why is filtration important in the PCB cleaning process?

Filtration plays a crucial role in maintaining the purity of cleaning fluids by removing contaminants, such as debris or fine particles, from the solution. This prevents these impurities from re-depositing onto the PCB surface during cleaning. Effective filtration ensures consistent cleaning quality, improves the efficiency of fluid recycling, and extends equipment life by reducing clogging. It also minimizes maintenance needs, helps maintain process stability, and reduces downtime, ultimately improving overall production efficiency.