In a PCB wet processing line, small parts can lead to large costs. A bit of chemistry leaking from the spray area can cause sticky rails and swollen bearings. It can also lead to uneven movement and more cleaning time. So, the water retaining roller, often called a water blocking roller in factories, should be seen as a key process part. Not just something you use up.

This guide shows how various water retaining roller materials work in actual PCB making. It focuses on splash control, resistance to chemicals, and contact at the edges.

Why a water retaining roller matters more than people think

Between steps like coating, developing, etching or stripping, and rinsing, liquid control is not always great. The edges of a moving panel push fluid out and spray tiny drops onto rails and nearby parts. Over time, this can cause issues.

Rails get dirty, which adds drag and leads to small stops.

Chemicals harm bearing spots and metal pieces close by.

The spray area turns into a spot that needs lots of upkeep.

Risk of defects goes up from extra dirt.

A water retaining roller fixes this by making a barrier at the edge. It touches the panel side lightly. It stops splash from the sides. And it sends liquid back to the tray instead of letting it spread.

Brand note (Qixingyuan): If your line wastes time on splash cleanup, Qixingyuan offers several water retaining roller material choices for PCB horizontal wet lines. They come with custom sizes to fit your setup.

Material selection: what each roller type is good at

Picking a water retaining roller is mostly about the material. The same form can act in different ways based on the polymer, firmness, and how the surface deals with buildup.

A helpful way to view it:

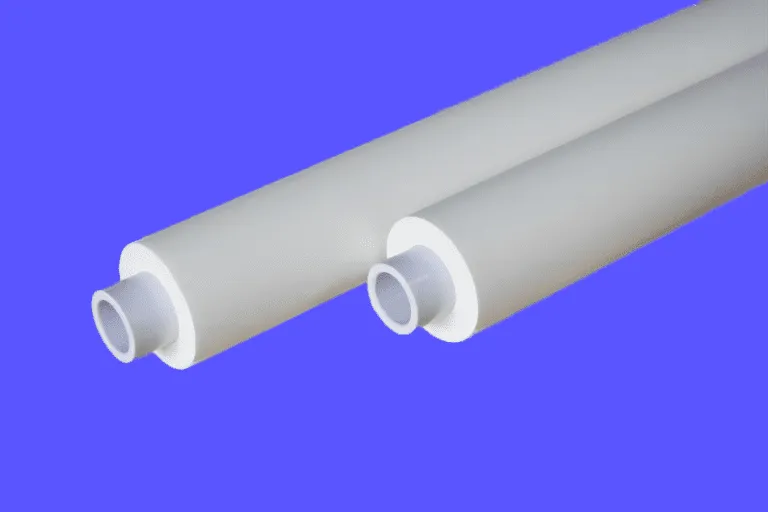

PP types are usually firmer and keep their shape well.

EPDM or TPV types give softer touch and better seal.

Teflon-like surfaces get picked when buildup and harsh chemicals are the big problems.

Quick comparison table for common water retaining roller materials

| Roller material/type | Chemical resistance | Heat resistance (typical) | Typical hardness | Common placement on PCB lines | What you gain |

| Teflon rubber roller | Strong acid/alkali | High-temp capable | Varies by build | Aggressive chem + build-up areas | Lower residue build-up, strong chemical tolerance |

| PP water retaining / water blocking roller | Acid/alkali | ~100°C | 90–105 | General wet zones, splash edges | Stiff edge control, stable geometry |

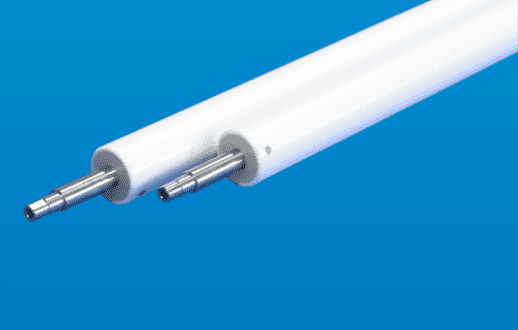

| PP thru-axis rubber roller (transmission) | Acid/alkali | ~100°C | 90–105 | Conveying sections that transmit motion | Better concentricity and drive stability |

| PP grooved transmission roller | Acid/alkali | ~100°C | 90–105 | Transmission + guidance where tracking matters | More controlled motion, reduced micro-slip |

| PVC/EPDM rubber roller | Weak acid/alkali | ~55°C | 60–70 | Mild chemistry + strong runoff need | Softer seal, good runoff behavior |

| TPV rubber roller | Strong acid/alkali | ~110°C | 55–65 | Higher temp zones + chemical exposure | Elastic contact with better heat headroom |

For buyers who aim to keep spares the same, Qixingyuan’s water retaining roller line includes PP, TPV, PVC/EPDM, and Teflon rubber rollers. They allow changes based on drawings. So, you can use one spec across areas.

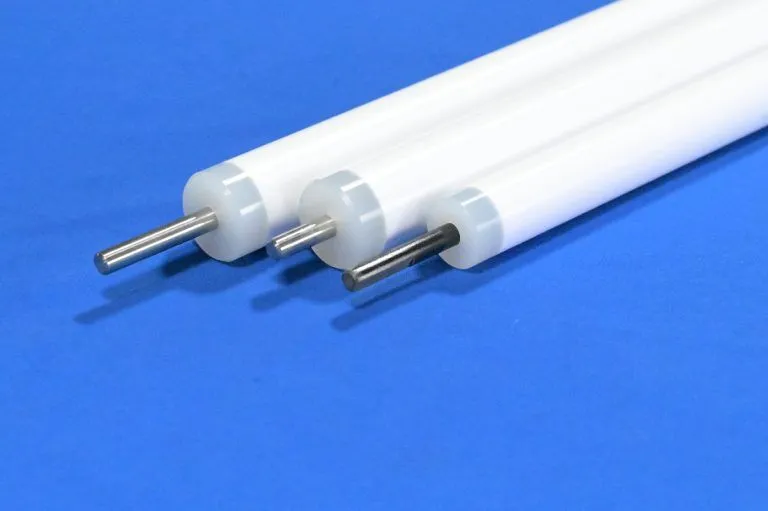

Spotlight: why Teflon rubber rollers are often the “problem-solver” choice

Teflon rubber rollers get picked when the spray area is rough on chemicals and messy in use. That means you spot buildup, swelling, or quick wear with regular materials.

Where Teflon-type surfaces earn their cost back

A usual case: a coating or spray step runs okay for days. Then, side rails feel tacky. Workers change speed or spray force to fix it. But that hides a rising danger: shaky movement and more cleanup often.

Teflon-like roller surfaces get chosen since they cut down on sticking. They slow buildup too. In real terms, this means less wiping each day and steadier edge touch over time.

Practical buying notes for Teflon rubber rollers

When you get a water retaining roller for this area, the key questions are not just “Is it Teflon?” Instead, ask:

What chemicals touch the roller edge? Are they acidic, basic, or mixed?

Does the roller sit near a hot part where heat rises?

Do you battle buildup like sticky fog, or mostly just splash?

A Teflon rubber roller is a frequent upgrade when both harsh chemicals and cleanup downtime happen.

If your spray or coating step wears out rollers fast, Qixingyuan can provide Teflon rubber water retaining roller choices made for strong acid/alkali use. Sizes match your shafts and brackets. So, no need to change the area.

Geometry choices: thru-axis, grooved, and standard PP rollers in transmission zones

Not all water retaining rollers just stop liquid. In many PCB wet lines, they also lead panels or pass motion. So, shape turns into a key choice for how it works.

If the roller helps drive, steadiness and even spin matter a lot. If it only stops splash, seal touch and surface action count more.

PP thru-axis rubber roller for stable transmission

A thru-axis setup is often picked when you want steady spin and sure drive after changes. It suits lines where:

Panels shift or you notice slight speed differences across the width.

Faster runs make tiny balance problems show as shakes.

You seek the same movement after fixes.

This sort of water retaining roller acts as both a splash stopper and a moving part.

PP grooved roller when tracking and wet grip matter

Grooves help when the line needs better control in wet spots where flat surfaces slide on water. A grooved water retaining roller gets chosen when:

You spot small slips in damp areas.

Spacing or timing downstream gets uneven.

Workers say “it pulls at times, slides at others.”

Standard PP water blocking roller for general wet zones

If the chief aim is to stop side splash rather than pass motion, a basic PP water retaining roller is used a lot. It’s a standard choice for usual wet areas and rinse parts. It keeps form well and stays steady in many acid or alkali settings.

If your line has rollers for splash stop and moving, Qixingyuan can offer PP thru-axis, PP grooved transmission rollers, and standard PP water retaining rollers. This way, upkeep teams use one seller and one drawing type across spots.

How to specify the right water retaining roller for purchasing

Buying teams often hear asks like “need water blocking roller, like the old one.” That’s how the wrong firmness or material gets in. And the spray area worsens, not improves.

Here’s a list for buying to stop reorder errors.

Spec checklist that prevents wrong reorders

Media touch: strong acid/alkali vs light chemicals.

True heat at the roller, not room heat: ~55°C vs ~100°C vs ~110°C areas count.

Role: splash only or motion pass like drive or lead.

Firmness goal:

Soft seal around 55–70 for better edge touch and flow control.

Firm control around 90–105 for steady shape and motion behavior.

Surface: flat vs with grooves.

Fit: thru-axis vs shaft tips vs your drawing norm.

Spin evenness need if the roller passes motion.

Fast troubleshooting table for maintenance + purchasing

| Symptom in the wet zone | Likely cause | What to change in the next water retaining roller order |

| Rails/bearing seats keep getting contaminated | Roller not sealing edge, too hard or wrong profile | Consider softer TPV or PVC/EPDM range, or adjust diameter/contact pressure |

| Roller swells / deforms early | Chemistry mismatch | Move to higher chemical resistance (often Teflon-type or a better-suited polymer) |

| Slip or unstable panel movement | Wet hydroplaning or weak transmission stability | Consider grooved PP transmission roller or a PP thru-axis build |

| Frequent cleaning due to sticky build-up | Coating mist accumulating on roller | Consider a Teflon rubber roller to reduce sticking and residue |

If you want less “wrong part” reorders, Qixingyuan backs drawing-based changes. They supply many water retaining roller materials like PP, TPV, PVC/EPDM, Teflon rubber. This helps you keep specs by area instead of guessing from old ones.

About Shenzhen Qixingyuan Machinery Equipment Co., Ltd.

Shenzhen Qixingyuan Machinery Equipment Co., Ltd. sits in Shenzhen, China. It acts as a trusted source for parts. The firm deals in spare items and gear for PCB horizontal wet processing lines. Their goods cover many rollers and items you throw away. These help in tasks like putting on coats, cutting with acid, making images clear, and washing off.

What makes Qixingyuan stand out? They know a lot about how parts act in actual plants. For instance, they get how rollers mix with spray spots, moving areas, and tough chemicals. This know-how stops tiny build mistakes from leading to huge troubles on the shop floor. Things like time off work or bumpy runs.

Buyers who seek a solid chain of goods gain from teaming with Qixingyuan. They give a broad set of water retaining rollers. These come in stuff like PP, TPV, PVC/EPDM, and Teflon rubber. Also, they make custom picks from your sketches. This makes sure parts slot in just right. No need to tweak your rig.

If your crew wants to make seller handling simple for wet-line care, Qixingyuan eases it. You can grab many kinds of rollers from one spot. Sizes and details match your tools. This way saves hours, cuts slip-ups, and holds your PCB lines going without hitches. In the end, Qixingyuan is a wise pick for good spare parts. These back up smooth making.

Conclusion

A water retaining roller is a cheap part with big effect on process. The best pick rests on spot like splash only vs motion, chemical touch like light vs strong acid/alkali, and what the line wants more: firm edge hold often PP or softer seal often TPV or PVC/EPDM. When buildup and rough chemicals rule, a Teflon rubber roller is usually the real fix. It fights harsh stuff and cuts down on dirt-linked shifts in work.