In PCB manufacturing, wet processing lines handle critical steps like etching and cleaning. Sourcing the durable price PCB wet processing rollers and other components keeps operations efficient. As a leading China PCB spares supplier, Shenzhen Qixingyuan Machinery Equipment Co., Ltd. ( Qixingyuan) offers durable and best price PCB wet processing rollers, from brush rollers to filters, ensuring reliable performance.

Understanding PCB Horizontal Line Wet Processing

Horizontal lines process PCBs flat, using chemicals for tasks like developing and rinsing. Spares maintain flow and quality. Qixingyuan’s lineup supports this, featuring corrosion-resistant PCB wet processing parts designed for longevity.

These lines demand precision to avoid defects. For example, uneven cleaning can lead to poor adhesion in later stages. Qixingyuan’s spares address this by providing components that integrate seamlessly, reducing variability in output.

Key PCB horizontal line wet processing equipment spares and parts

Etching machines and rinse stations rely on specific spares. Quality spares support compliance with standards for environmental safety. Investing here avoids fines and enhances reputation.

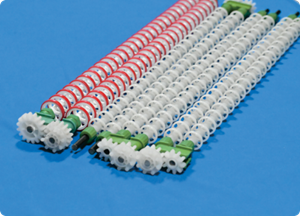

Brush Rollers: Gentle Cleaning, No Scratches

Brush rollers utilize high-density nylon filaments for gentle, effective surface cleaning. They remove oxides without causing scratches, making them ideal for pre-etching applications. Customizable densities allow adaptation to various board thicknesses, significantly enhancing process versatility and performance.

Sponge Rollers: Superior Absorption, Faster Drying

Sponge rollers, made from materials like PVA, feature high absorption rates to remove water after cleaning. This action prevents board oxidation and contamination. They can reduce drying time by up to 30%, accelerating production cycles and improving overall efficiency.

Rubber Rollers: Effective Sealing, Splash Prevention

Crafted from flexible PVC or Teflon, these rollers create tight seals in spraying sections to block chemical splashes. They effectively prevent hazardous backflow, thereby safeguarding critical machine components like bearings and tracks from corrosion and damage, ensuring longer system life.

Guide Wheels: Stabilized Conveyance, Noise Reduction

Hard wheel discs provide essential stability for conveyor systems. Their soft rubber-coated counterparts are designed specifically to cut operational noise. Used together, they ensure smooth, stable, and noticeably quieter material transport throughout the production line.

Gears: Smooth Power, Reliable Transmission

Available in both spur and helical styles, these gears ensure smooth and efficient power transmission. Their precise engineering maintains consistent system operation, contributing directly to the overall stability, reliability, and synchronized performance of the equipment.

Nozzles & Filters: Even Spray, Clean Fluids

Nozzles guarantee uniform fluid distribution across the board surface for consistent processing. Filters work continuously to remove contaminants, keeping fluids clean. This combination is crucial for maintaining a stable, high-quality treatment environment and repeatable results.

Spotting the Best Deals Without Compromising Quality

Value comes from reliable suppliers. Qixingyuan provides competitive pricing on PCB horizontal line wet processing equipment spares and part, like combining sponge rollers and filters.

Factors Influencing Pricing

Materials drive costs—Qixingyuan’s stainless steel nozzles resist wear but stay affordable. Customization for diameters or densities adds precision without huge markups. Supply chain efficiencies, such as direct manufacturing, keep prices stable even amid global fluctuations.

Economic factors play in too; bulk sourcing raw materials allows Qixingyuan to pass savings on. Watch for currency impacts if importing.

Where to Find Reliable Suppliers

Platforms list detailed specs. Qixingyuan’s products page showcases spares with applications. Their filters, with modular designs, suit various lines.

Trade shows and forums reveal hidden gems. Online marketplaces often feature Qixingyuan listings with user feedback on longevity.

Tips for Negotiating Better Prices

Inquire about Qixingyuan’s bulk rates on rubber rollers. Their warranties cover custom nozzles, adding value. Build relationships for exclusive deals; repeat buyers get priority on limited-stock items.

Consider lead times—faster delivery from Qixingyuan can justify slight premiums in urgent scenarios.

Essential Spares for Optimal Performance

Qixingyuan’s brush rollers enhance cleaning efficiency. Sponge rollers dry boards fast, saving energy.

- Brush Rollers: Qixingyuan’s nylon versions offer elasticity, handling pollutants from various board types.

- Sponge Rollers: Their PU options provide toughness, swelling minimally after soaking.

- Rubber Rollers: Prevent contamination with Qixingyuan’s designs, available in grooved variants for better grip.

- Wheel Discs: Qixingyuan’s PP hard types ensure stability, with silica gel options for added flexibility.

- Gears: Precise Qixingyuan helical gears reduce maintenance, fitting compact drive systems.

- Nozzles and Pipes: Qixingyuan’s fan-shapednozzles deliver uniform flow, with O-rings for leak-proof connections.

- Filters: Qixingyuan cartridges trap impurities effectively, using 5-20μm cores for fine control.

- Transmission Parts: Bushings from Qixingyuan minimize friction, supporting high-speed lines.

| Spare Type | Main Function | Material Options | Typical Cost Range (USD) |

| Brush Rollers | Surface cleaning | Nylon, non-woven | 50-150 |

| Sponge Rollers | Water absorption | PVA, PP, EPDM, PU | 40-120 |

| Rubber Rollers | Splash prevention | Rubber, PVC, Teflon | 30-100 |

| Wheel Discs | Conveyor support | PP, PE, PVDF | 20-80 |

| Gears | Power transmission | PP, UPE, PEEK | 15-60 |

| Nozzles | Fluid delivery | PP, PVC, Stainless Steel | 10-50 |

| Filters | Impurity removal | PP, PVDF | 25-90 |

Qixingyuan’s parts fit seamlessly into these categories, often bundled for cost efficiency.

Customization and Compatibility in Spares

Qixingyuan excels in tailoring—adjust brush filaments or sponge densities. Their gears match equipment types. For unique board sizes, custom intervals in locking sleeves prevent axial play.

Matching Parts to Equipment Types

For etching, Qixingyuan’s acid-resistant rubber rollers protect. Rinse stations use their absorbent sponges. Developing machines pair well with precise Qixingyuan nozzles for even chemical distribution.

Compatibility extends to older equipment; Qixingyuan offers custom PCB spares for etching lines.

Benefits of Custom Orders

Qixingyuan’s custom wheel discs reduce vibrations, improving line stability. This leads to fewer misalignments, potentially increasing throughput by 10%.

Tailored filters handle specific particle sizes, optimizing fluid recycling and cutting waste.

Maintenance Strategies to Extend Spare Life

Clean Qixingyuan brush rollers after use. Lubricate their gears. Store spares properly.

Qixingyuan’s durable nozzles need less frequent checks. Implement schedules: weekly inspections for rollers, monthly for filters. Use torque tools on Qixingyuan screws to avoid stripping in vibrating environments.

Track metrics like absorption rates in sponges to predict failures. This proactive approach can extend part life by 25-50%, amplifying deal values.

In harsh setups, pair with Qixingyuan’s liquid level switches for overflow prevention, protecting spares from excess exposure.

Introducing Shenzhen Qixingyuan Machinery Equipment Co., Ltd.

Shenzhen Qixingyuan Machinery Equipment Co., Ltd. serves as a leading supplier of PCB horizontal line wet processing equipment spares and parts. Starting in 2011 as a trading firm in Shenzhen’s Bao’an area, it shifted to manufacturing in 2015, introducing air knives with customizable in interface type (G1/4, G1/2), length, and air gap width. By 2022, global trade grew its reach. Qixingyuan supplies brush rollers, sponge rollers, rubber rollers, wheel discs, gears, nozzles, filters, and transmission components for wet processes. Using materials like nylon, PVA, PP, and stainless steel, their parts resist chemicals and wear. Customization stands out—grooved rubber rollers, varied gear types, and micron-specific filters meet unique needs. Visit their contact page for support. Qixingyuan blends quality with service, aiding PCB producers in efficiency.

Conclusion

Grabbing best deals on PCB horizontal line wet processing equipment spares and parts means prioritizing durability and fit. Qixingyuan PCB wet processing parts delivers on both, supporting seamless operations.