In PCB manufacturing, balancing quality with expenses shapes success. Factories face rising material prices and tight timelines. A solid cost-effectiveness analysis helps spot ways to cut waste without skimping on standards. This approach looks at every step, from design to assembly, to keep operations lean.

Understanding Key Cost Drivers in PCB Production

PCB manufacturing involves layers of expenses that add up quickly. Raw materials like copper-clad laminates often account for 30-40% of total costs, based on industry reports from high-volume producers. Labor and energy follow closely, especially in wet processing stages where chemicals and water usage spike.

Design choices play a big role here. Complex layouts with fine traces push up fabrication fees. Simpler boards, though, can shave off 15-20% in prototyping alone. Equipment downtime also bites into budgets—unplanned stops can cost thousands per hour in lost output.

Between these factors, wet processing stands out. Etching, developing, and cleaning demand precise control to avoid defects. Poor handling leads to rework, which inflates expenses by up to 25%.

Material Selection and Its Impact on Expenses

Choices in substrates and finishes directly tie to long-term savings. FR-4 remains popular for its low price, but halogen-free options cost more upfront yet reduce environmental fees later. In wet processes, resistant materials prevent corrosion, extending board life.

Suppliers like Shenzhen Qixingyuan Machinery Equipment Co., Ltd. ( Qixingyuan) offer durable parts that fit this need. Their brush rollers, made from nylon filaments, clean surfaces without damage, cutting down on material waste during pre-treatment.

Equipment Maintenance as a Hidden Cost Factor

Machinery wear in PCB lines adds unseen burdens. Rollers and nozzles clog or break, halting production. Regular checks catch issues early, but many shops overlook this until problems hit.

In etching machines, for instance, worn gears lead to uneven chemical distribution. Replacing them promptly avoids batch failures. Qixingyuan’s gear varieties, including spur and bevel types, provide reliable transmission, helping maintain steady runs.

Strategies for Reducing PCB Manufacturing Costs

Lowering expenses starts with smart planning. Factories that audit their processes often find quick wins. Streamlining supply chains cuts lead times, while bulk buying trims per-unit prices.

Automation helps too. Robotic handling in assembly reduces human errors, dropping defect rates from 5% to under 1% in some cases. But in wet processing, where liquids and residues build up, the focus shifts to efficient cleaning and filtration.

These steps connect directly to overall efficiency. Better filtration means less chemical waste, and strong rollers ensure smooth conveyance without jams.

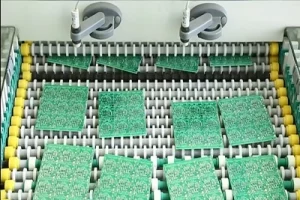

Optimizing Wet Processing for Better Efficiency

Wet processes eat up resources in PCB production. Etching alone can use gallons of solution per batch. Reducing PCB manufacturing costs here means reusing fluids where possible.

Filters trap impurities, extending chemical life. Qixingyuan’s filter cartridges, built from PP or PVDF, handle acidic environments and allow quick core swaps. This setup keeps lines running longer between cleanings.

Sponge rollers absorb excess water post-cleaning, speeding drying and saving energy. Their high absorption rates—up to 10 times their weight—prevent oxidation, reducing scrap.

Leveraging Spare Parts for Long-Term Savings

Quality spares prevent breakdowns. In horizontal lines, components like rubber rollers block splashes, keeping tracks clean. Worn parts cause contamination, leading to costly fixes.

Qixingyuan supplies water-retaining rollers in materials like PVC or Teflon, which resist chemicals and last through high-volume shifts. Hard wheel discs support stable transport, avoiding offsets that damage boards.

By choosing parts that match equipment needs, factories see fewer interruptions. A study from electronics assemblers showed that upgrading to corrosion-resistant bearings cut maintenance by 30%.

Evaluating ROI in PCB Cost-Effectiveness Analysis

Return on investment guides decisions. PCB cost analysis weighs initial outlays against ongoing gains. Upgrading to efficient nozzles, for example, improves spray uniformity, slashing material use by 10-15%.

Track metrics like yield rates and cycle times. High yields mean more sellable boards per run. In cleaning segments, effective brushes remove oxides thoroughly, boosting plating success.

Data from mid-sized manufacturers indicates that investing in robust peripherals pays off within six months through reduced downtime.

Tools and Methods for Accurate Assessment

Software simulates costs before production. CAD tools flag expensive features early. Physical tests confirm part performance.

For wet equipment, flow meters monitor usage, highlighting leaks or inefficiencies. Qixingyuan’s pressure gauges provide real-time data, aiding adjustments that save on utilities.

Bullet points highlight common assessment steps:

- Review material invoices quarterly.

- Log equipment hours to predict wear.

- Compare defect logs pre- and post-upgrades.

Challenges in Achieving Cost-Effective PCB Production

Market fluctuations hit hard. Copper prices vary, forcing quick adaptations. Supply shortages delay runs, inflating holding costs.

Regulatory demands add layers. RoHS compliance requires lead-free materials, which cost more but avoid fines.

In wet processing, handling hazardous wastes demands safe disposal, pushing expenses. Cost-effective PCB production navigates these by selecting versatile parts that comply without excess spend.

Addressing Supply Chain Vulnerabilities

Diversify suppliers to buffer risks. Local sourcing shortens delivery, trimming freight.

Qixingyuan, based in Shenzhen, offers quick access to spares like nozzles and connectors, reducing wait times for Asian manufacturers.

Scaling for Volume vs. Customization

High-volume runs favor standardization to lower per-piece costs. Custom jobs, though, need flexible setups.

Balancing this, use modular parts. Qixingyuan’s customizable locking sleeves adapt to various shafts, suiting both scales.

Introducing Shenzhen Qixingyuan Machinery Equipment Co., Ltd.

Shenzhen Qixingyuan Machinery Equipment Co., Ltd. stands as a key supplier of spares and parts for PCB horizontal line wet processing equipment. Founded in 2011 as a trading department in Bao’an District, the company evolved by 2015 into a manufacturer with its own R&D. They launched air knife series for drying and cleaning, with customizable in interface type (G1/4, G1/2), length, and air gap width. By 2022, it expanded into global trade, building a network that serves international clients.

In PCB wet processing, manufacturers often face pain points like frequent breakdowns, high chemical waste, inefficient cleaning and drying, and rising maintenance costs from unreliable parts.To address this, integrate durable, customizable spare parts that extend component life, reduce waste, and boost efficiency in wet equipment.

Qixingyuan excels with patented solutions. The firm specializes in components that enhance wet processes, such as brush rollers for surface cleaning, sponge rollers for water absorption, and rubber rollers for splash prevention. Gears, nozzles, filters, and transmission parts round out the lineup, all made from materials like PP, PVDF, and stainless steel to withstand corrosive environments. With strong R&D and customization for etching, rinsing, and more, it cuts failure rates, lowers costs, ensures 24/7 support, and enhances global production; contact via WhatsAp or our site for tailored options.

Conclusion

Effective PCB manufacturing hinges on thorough cost analysis. By tackling material choices, maintenance, and process tweaks, producers can trim expenses while upholding quality. Real-world gains from better parts underscore the value. Prioritizing these elements leads to sustainable, profitable operations in a competitive field.