In PCB horizontal wet process lines, conveyor stability is often underestimated. Yet most quality losses, tracking errors, and unexpected downtime start with small mechanical inconsistencies in PCB conveyor parts. Rollers, gears, and bearings work together under water, chemistry, and continuous load. When one element drifts out of tolerance, the entire line feels it.

This article explains how core PCB conveyor parts affect throughput and yield, what failure modes appear first in real production, and how practical maintenance decisions reduce long-term operating cost. The focus is on real factory scenarios rather than theory, helping equipment owners and maintenance teams make better purchasing and replacement decisions.

Why conveyor stability matters more than speed

In wet process sections, boards move through narrow mechanical windows. Clearance between panel edges, guide rails, and transfer elements is small. When motion is stable, boards track straight and process results remain consistent. When friction or alignment changes, even slightly, the impact spreads quickly to downstream steps.

Most conveyor issues do not fail suddenly. Instead, friction changes, load increases, wear accelerates, and alignment slowly drifts. This is why condition-based maintenance is far more effective than waiting for visible damage.

From a system view, most wet-line conveyor problems fall into three areas: transfer elements such as rollers and wheel discs, torque transmission through gears, and support components including bearings, bushings, and shafts.

Shenzhen Qixingyuan Machinery Equipment Co., Ltd. ( Qixingyuan) supplies a wide range of PCB conveyor parts designed for wet and corrosive environments, including wheel discs, plastic bearings, gears, shaft sleeves, and fastening components. These parts are built to maintain stable motion under continuous exposure, helping lines reduce tracking-related defects and avoid unnecessary stoppages.

Conveyor rollers and wheel discs: where friction becomes yield

Rollers and wheel discs do more than move boards forward. They define how force enters the PCB, how vibration is absorbed, and how well the conveyor tolerates warped or thin panels.

Hard wheel discs for consistent tracking

Hard wheel discs are typically used where precise geometry and stable support are required. They are effective in reducing board drift and preventing edge rubbing, especially in longer transfer sections.

In real production, repeated misalignment at the same station often points to uneven disc wear rather than material failure. A polished wear zone on one side usually indicates side loading from misaligned guides. Correcting guide alignment often extends disc life more effectively than changing disc material.

Soft and rubberized wheel discs for shock and noise control

Soft or rubberized wheel discs are commonly used to reduce vibration, noise, and slipping during acceleration. They are particularly useful when operators notice intermittent vibration marks or audible squealing during transfer.

Over time, rubberized surfaces may glaze or harden, especially after frequent cleaning cycles or temperature changes. This leads to unstable friction rather than immediate failure. Monitoring surface condition and rotation resistance helps identify replacement timing before slip affects yield.

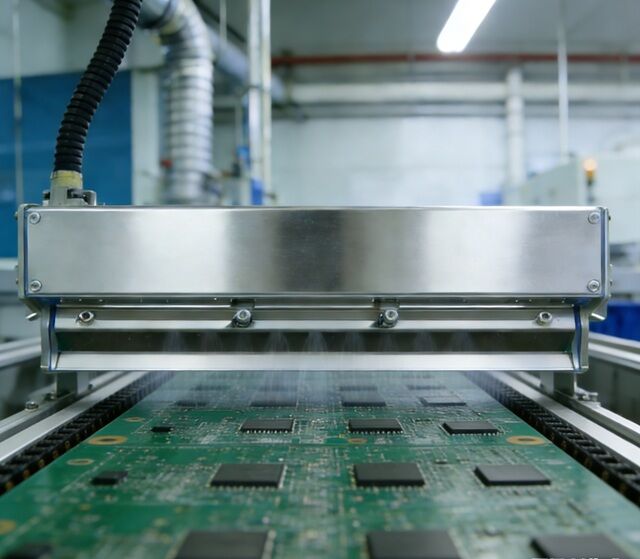

Water-blocking rollers near spray and coating stages

Near spraying, coating, or printing sections, liquid splash control protects both cleanliness and mechanical life. Chemical intrusion into rails or bearing seats is a common cause of repeated bearing failure.

Water-blocking rollers help prevent backflow and splash migration, reducing contamination buildup and cleaning frequency.

Qixingyuan provides hard wheel discs, soft rubberized wheel discs, and water-retaining rollers as part of its PCB conveyor parts range. These components help stabilize friction, reduce vibration-related defects, and typically cut maintenance interventions by preventing contamination-driven wear.

Gears in wet-line conveyors: precision under variable load

Conveyor gears in PCB equipment experience frequent starts, speed changes, and load variations. When gear transmission is stable, board spacing and timing remain consistent. When it is not, vibration, noise, and accelerated wear appear.

Early signs of gear wear

Gear failure rarely starts with broken teeth. Early signs include slight ticking sounds, fine debris near guards, or increased backlash felt during inspection. These symptoms often appear before speed instability becomes visible on the line.

In wet environments, residue can behave like abrasive paste. If contamination is not controlled, even well-selected materials will wear faster than expected.

Material selection in real applications

Choosing gear material is less about strength alone and more about dominant failure mode. If chemical exposure is the main issue, corrosion-resistant engineering plastics may outperform metal. If torque spikes are frequent, alignment and friction stability should be corrected before upgrading materials.

Qixingyuan supplies spur, bevel, helical, pin, and combined gears as PCB conveyor parts, with material options suitable for wet processing. Proper gear fit and material selection help reduce transmission-related downtime and support predictable replacement cycles.

Bearings, bushings, and shafts: hidden sources of instability

When conveyor issues persist after roller replacement, the root cause is often in support components rather than visible transfer parts.

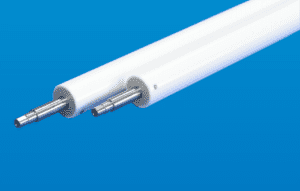

Plastic bearings in wet environments

Plastic bearings are widely used in PCB wet lines because they resist corrosion and can operate with minimal lubrication. However, their most common failure mode is residue buildup rather than material fatigue.

Gradual increases in drag, uneven rotation, or localized noise often point to contamination ingress rather than bearing wear. Identifying splash paths and residue sources usually solves the problem more effectively than repeated bearing replacement.

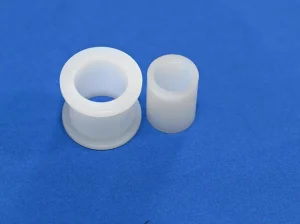

Bushings and shaft sleeves

Bushings and shaft sleeves keep shafts centered and reduce friction. Misalignment can create uneven wear that looks like material failure but is actually a geometry issue. Small angular errors can shorten bushing life significantly.

Locking sleeves and fasteners

Axial movement is a frequent but overlooked issue. If locking sleeves loosen, shafts shift, spacing changes, and edge contact becomes intermittent. In wet environments, fasteners must also resist corrosion and vibration loosening.

Qixingyuan supplies plastic bearings, shaft sleeves, locking sleeves, and corrosion-resistant fasteners as part of its PCB conveyor parts portfolio. Properly selected support components help stabilize conveyance and reduce recurring alignment-related downtime.

A practical maintenance routine for PCB conveyor parts

Effective maintenance focuses on early indicators rather than visible damage.

Daily checks should include listening for new rhythmic noise, observing board tracking consistency, and comparing temperature between left and right conveyor components. In wet areas, residue accumulation should be addressed consistently rather than intermittently.

Weekly checks should focus on rotation freedom, wheel-disc surface condition, axial play, and gear backlash feel. Recording trends over time provides better insight than relying on memory.

A typical example involves board skew appearing after a spray section. Operators often tighten guides, which increases side load and accelerates wear. The correct fix usually involves controlling splash, restoring friction balance, and replacing worn components rather than increasing mechanical constraint.

By standardizing replacement parts and monitoring wear patterns, plants can convert emergency stops into planned interventions.

Qixingyuan supports maintenance-driven improvements by offering standardized, customizable PCB conveyor parts that fit existing equipment layouts. Preventing even one unexpected stop per month often justifies planned replacement programs in high-throughput wet lines.

About Shenzhen Qixingyuan Machinery Equipment Co., Ltd.

In many PCB factories, conveyor issues are treated as unavoidable wear. The real cost appears later in repeated adjustments, unstable tracking, and emergency maintenance. The underlying principle is simple: horizontal wet lines rely on consistent friction and alignment, and conveyor parts must be selected for chemical exposure and continuous operation.

Shenzhen Qixingyuan Machinery Equipment Co., Ltd. focuses on PCB horizontal line wet processing equipment spares and parts. Its product range includes wheel discs, gears, plastic bearings, shaft sleeves, locking sleeves, and fastening components designed for corrosive and high-duty environments. By matching materials and dimensions to real operating conditions, Qixingyuan helps customers move from reactive fixes to predictable maintenance planning.

Conclusion

Stable wet-line conveyance depends on system balance rather than any single component. Rollers define friction, gears control timing, and bearings maintain alignment. When these PCB conveyor parts are selected for real failure modes and maintained with simple trend-based checks, lines run more smoothly, troubleshooting becomes easier, and yield remains consistent.

What are the earliest signs that PCB conveyor parts need attention?

The earliest signs that PCB conveyor parts need attention often include subtle changes like unusual noises, increased friction at one station, or repeated skewing of the boards. These issues usually indicate that components like wheels, bearings, or rollers are wearing down or misaligned. Rather than just adjusting settings, it’s crucial to inspect these parts early to prevent potential damage, reduce unplanned downtime, and ensure smooth production continuity.

How do I choose between hard and soft wheel discs?

Hard wheel discs are ideal for providing stable geometry and precise tracking control, making them perfect for applications that require consistent movement. On the other hand, soft wheel discs excel at absorbing vibrations and preventing slipping, improving stability in high-speed or heavy-load operations. The choice between the two should be based on the specific operational challenge—whether it’s maintaining accuracy or minimizing vibration and impact—rather than just material preference.

Why do plastic bearings fail in wet PCB lines?

Plastic bearings in wet PCB lines typically fail due to residue buildup and misalignment rather than corrosion. These conditions can result in the bearings seizing up or becoming less effective over time. Controlling water splashes and maintaining a proper cleaning pathway for the bearings can significantly extend their life. It’s important to regularly inspect alignment and cleanliness, as these factors can often prevent premature failure, even more than material upgrades.

What causes fast gear wear in conveyor drives?

Fast gear wear in conveyor drives is typically caused by contamination, misalignment, and torque spikes resulting from unstable friction. When debris or lubrication issues occur, gears can grind against each other, increasing wear. Misalignment also accelerates uneven wear and increases stress on the gear teeth. Addressing these root causes—such as ensuring proper alignment, cleaning, and lubrication—will usually extend gear life significantly, often more effectively than upgrading the materials used for the gears.

Can standardized spare parts reduce downtime?

Yes, standardized spare parts such as wheel discs, bearings, bushings, and fasteners can significantly reduce downtime. By keeping these parts readily available, manufacturers can quickly replace worn components instead of waiting for customized replacements. This not only shortens diagnostic and repair times but also minimizes unplanned production stops. Having matched spare parts on hand ensures smoother operations, reduces delays, and prevents costly downtime, making it a wise investment for maintaining production continuity.