In the fast-paced world of electronics, printed circuit boards (PCBs) form the backbone of countless devices. Manufacturers face constant pressure to deliver reliable products on time. Yet, small details often make the biggest difference. High-quality accessories stand out as a vital factor in achieving PCB manufacturing success. These components, from rollers to filters, directly influence production efficiency and product quality.

Common Hurdles in PCB Production

PCB manufacturing involves intricate steps like etching, cleaning, and plating. Issues arise when equipment fails to perform consistently. For instance, unclean board surfaces lead to defects in subsequent layers. Oxidation from residual moisture can ruin entire batches. Equipment downtime from worn parts adds costs and delays.

Such problems highlight the need for dependable parts. A study from the IPC (International Printed Circuit Association) shows that 70% of production defects stem from equipment-related issues. Factories dealing with high-volume runs see rework rates climb without proper maintenance. This not only wastes materials but also erodes profit margins.

Moving beyond these challenges requires focusing on the tools that keep lines running smoothly. Accessories tailored for wet processing steps play a key role here.

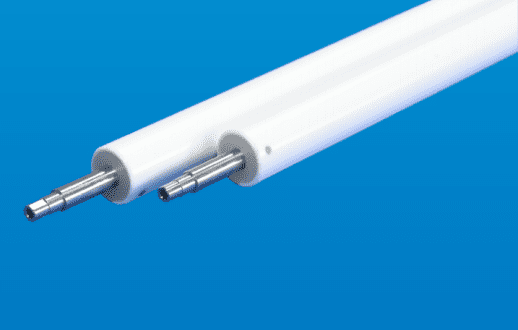

Shenzhen Qixingyuan Machinery Equipment Co., Ltd. ( Qixingyuan) addresses these common hurdles with reliable solutions like brush rollers and sponge rollers, designed for thorough cleaning and moisture removal in PCB lines. These products, made from durable nylon and polymer materials, reduce defects and downtime, supporting manufacturers in achieving consistent PCB manufacturing success.

How Accessories Drive Efficiency in Wet Processing

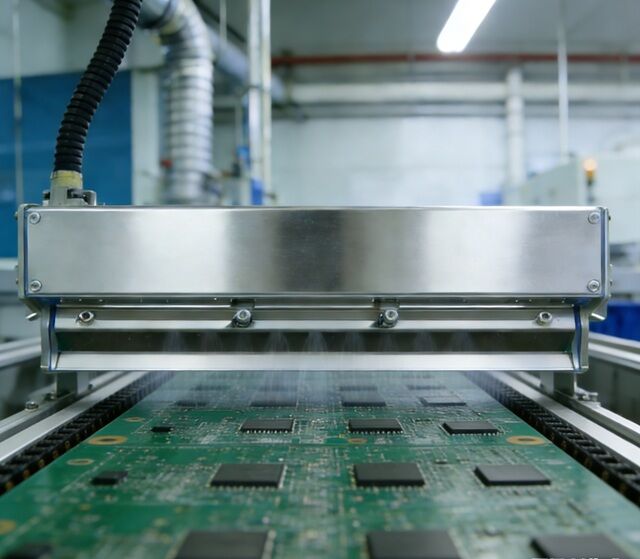

Wet processing covers critical phases in PCB creation, including cleaning, developing, and etching. Here, high-quality accessories ensure precise control over liquids and movements. Think about cleaning segments where board surfaces must be spotless. Low-grade brushes might leave residues, causing adhesion failures in plating.

PCB cleaning defects often lead to subsequent layer defects and batch scrapping. Low-quality brushes leave residues or fail to clean thoroughly.In one case, a mid-sized electronics firm switched to durable brush rollers with high-density filaments. This change cut cleaning defects by 25%. The rollers’ elasticity prevented board damage while removing oxides effectively. Similarly, sponge rollers absorb excess water post-cleaning, reducing oxidation risks and energy use in drying.

Accessories like water-retaining rollers prevent splashes in spraying areas. Made from flexible, corrosion-resistant materials, they keep equipment clean and extend machine life. Factories report fewer maintenance stops, with some seeing uptime rise by 15%.

These examples show how selecting the right parts transforms operations. But the benefits extend to conveyance and transmission too.

Enhancing Conveyance and Stability

Stable board movement is essential in horizontal lines. Misalignments cause scratches or jams, halting production. Hard wheel discs and soft rubberized wheel discs provide strong support without deformation. Their wear-resistant designs handle heavy loads, ensuring smooth transport.

PCB conveyor misalignment causes scratches or jams, halting production. This is caused by the wheel potentially deforming or due to excessive friction. An assembly plant integrated these discs and saw throughput increase by 10%, thanks to fewer offsets.

For flipping mechanisms, specialized flipping machine wheel discs offer low-friction rotation. This precision reduces stalling, boosting line speed. In a real-world setup, an assembly plant integrated these discs and saw throughput increase by 10%, thanks to fewer offsets.

Intermediate wheels, flange wheels, and plastic bearings guide boards accurately. Their corrosion resistance suits harsh chemical environments. Plants using these report lower deviation rates, protecting tracks and improving overall flow.

Such stability minimizes waste. When boards move without issues, yield rates climb, directly tying back to PCB manufacturing success.

Precision in Transmission and Filtration

Transmission parts keep everything synchronized. Gears—including spur, bevel, and helical types—must withstand constant wear. High-strength materials with precise tooth profiles ensure smooth power transfer. Worn gears lead to vibrations, but quality ones cut maintenance by 30% in some facilities.

Spacer sleeves and locking sleeves secure shafts, eliminating play. This tight fit maintains alignment, vital for high-speed runs.

Filtration is equally important. Impurities in liquids clog nozzles and damage pumps. Filter accessories, with options like cartridges and screens, trap particles effectively. A PCB line using advanced filter cartridges with 5-20μm pores avoided frequent clogs, slashing downtime by 20%.

Nozzles and pipes complete the picture. Fan-shaped or conical nozzles deliver even sprays, while durable spray pipes resist corrosion. These ensure uniform coatings, reducing defects.

Together, these elements form a reliable system. But monitoring tools add another layer of control.

Qixingyuan enhances wet processing efficiency through its range of high-quality accessories, such as water-retaining rollers for splash prevention and filter cartridges for impurity removal. With materials like PP and PVDF for corrosion resistance, these customizable products help factories achieve 15-25% reductions in defects and energy use, driving overall PCB manufacturing success.

Monitoring and Control for Optimal Performance

Accurate data guides adjustments. Liquid level switches prevent overflows or dry runs with sensitive detection. Factories avoid costly damages, maintaining safe operations.

Pressure gauges and flow meters track system parameters. Quick responses to changes keep processes stable. In plating, this precision boosts layer uniformity, with some users noting 15% better yields.

Electroplating accessories like brackets and hangers withstand acids, supporting consistent results. Their durability cuts replacement needs.

Beyond core parts, peripheral items matter too. Glass rubber strips seal connections, preventing leaks. Grinding machine accessories ensure even surfaces prep.

All these contribute to a cohesive setup. Yet, sourcing from a trusted provider ties it together.

Qixingyuan supports optimal performance with monitoring tools like liquid level switches and pressure gauges, featuring high sensitivity and corrosion-resistant designs. Combined with electroplating accessories for stable plating, these products extend equipment life and improve yields by up to 15%, making them essential for reliable PCB manufacturing success.

The Impact on Yield and Cost Savings

High yields define success in PCB work. Defects from poor accessories can hit 5-10% of output. Quality ones flip this, pushing yields to 95% or higher.

Cost-wise, reliable parts lower long-term expenses. Initial investments pay off through reduced repairs. A report from Electronics Manufacturing Services notes that firms using premium spares save 20-30% on operational costs annually.

In competitive markets, this edge builds reputation. Consistent quality attracts clients, fostering growth.

Real scenarios back this.PCB etching unevenness leads to uneven circuits and product failures. An Asian PCB producer faced high rework from uneven spraying. Adopting corrosion-resistant nozzles and connectors stabilized flows, dropping defects by 18%. The solution’s durability meant fewer swaps, saving time and money.

Another plant struggled with transmission slips. Integrating robust gears and shaft sleeves smoothed operations, lifting efficiency by 12%.

These outcomes show clear links between accessories and results.

Long-Term Benefits for Manufacturers

Over time, quality builds resilience. Equipment lasts longer, scaling with demand. This reliability supports innovation, like adopting finer pitches in boards.

Environmental perks emerge too. Efficient drying and filtration cut waste, aligning with green standards.

For manufacturers, investing here means sustained PCB manufacturing success.

Qixingyuan drives yield improvements and cost savings with durable gears and nozzles, engineered for precision and longevity. Factories using these see 18-30% reductions in defects and operational costs, reinforcing Qixingyuan’s role in long-term PCB manufacturing success.

Accessories Lifespan Comparison Table

| Accessories | Inferior Accessories Lifespan | Premium Accessories Lifespan | Cost Savings |

| Brush Rollers | 1–2 months | 3–6 months | 40–60% |

| Filter Cartridges | 5–10 days | 15–30 days | 30–50% |

| Conveyor Rollers | 3–6 months | 12–24 months | 50–70% |

About Shenzhen Qixingyuan Machinery Equipment Co., Ltd.

PCB lines often grapple with persistent issues like inconsistent cleaning or frequent clogs, leading to halted production and rising scrap rates. These stem from subpar parts that fail under chemical stress or mechanical wear, disrupting fluid control and board handling.

The root lies in material mismatches and poor design. Accessories exposed to acids or high speeds degrade quickly, causing uneven processes and higher energy use.

Addressing this calls for specialized solutions in wet processing spares. Qixingyuan steps in as a dedicated supplier for PCB horizontal line equipment. Founded in 2011 and evolving through R&D since 2015, the company offers a wide array: brush rollers for thorough cleaning, sponge rollers for moisture removal, gears for steady transmission, and filter accessories for pure liquids.

Key strengths include corrosion-resistant materials like PP and PVDF, plus customization for exact fits. Clients see tangible gains—20% less downtime from durable nozzles and 15% yield boosts via precise wheel discs. With global reach since 2022, Qixingyuan delivers reliable, tailored parts that tackle pain points head-on, ensuring smooth, cost-effective runs.

Conclusion

Quality accessories form the foundation of effective PCB manufacturing. They tackle daily hurdles, boost yields, and cut costs. Manufacturers who prioritize them gain a clear advantage in reliability and efficiency.